IrgaCycle PS 031 G

IrgaCycle PS 031 G

IrgaCycle™ PS 031 G is a stabilizer and co-additive to increase the content of recycled polymers in polyolefin film applications.

This product is designed specifically for re-stabilization of post-consumer and post-industrial polyolefin-films during re-granulation or conversion steps. The product enhances the processing and long-term stability of the recycled plastics. It is especially suited for recycled LDPE and LLDPE; e.g. recycling streams originating from packaging films, wrap or shrink films, or other flexible packaging forms.

Designed to address:

- Gel formation

- Contamination with prooxidation species (e.g., metal ions)

- Inconsistent processing behavior

- Depleted initial stabilizer packages

- Presence of pre-oxidized polymer chains and low molecular weight oxidation products

- Insufficient shelf life of recyclate

Depending on the residual stabilizer content, quality, and oxidation state of the recyclate material, IrgaCycle PS 031 G is recommended in quantities from 0.1 to 0.5%.

Features & Benefits

- Improves film processing properties and maintains mechanical properties

- Help reducing gel formation

- Maintain melt flow during melt processing

- Rejuvenates depleted initial stabilizer packages in the polymer

Performance Data

Improved Processing of Film Grade rLDPE

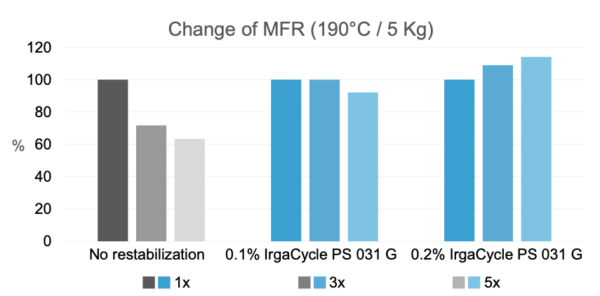

Processing stability

- Post-consumer

- Multi-pass, single screw extrusion at 220°C

- Melt Flow Rate (MFR) measured after 1, 3, and 5 extrusions

rLDPE shows signs of cross-linking and potential gel formation with reduced MFR. IrgaCycle™ PS 031 G efficiently stabilizes film processing with no indication of cross-linking.

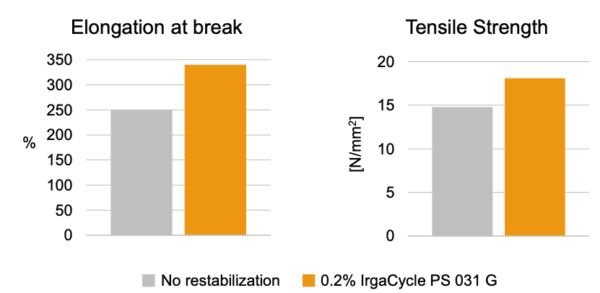

Improved Durability of rLDPE Films

Long-term stability

- Post-consumer

- Blown films, 30 µm

- Tensile strength and elongation at break improved with use of stabilizer

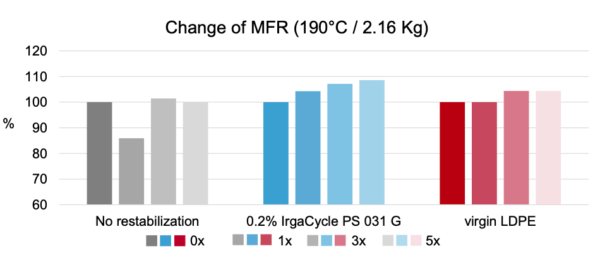

Stable Melt Processing of rLDPE

Processing stability

- rLDPE, extrusion grade

- Post-consumer

- Multi-pass extrusion at 220°C

- Melt Flow Rate (MFR) measured after 1, 3, and 5 extrusions

rLDPE demonstrates erratic MFR, first cross-linking (MDR decrease), followed by chain scission (MFR increase). IrgaCycle™ PS 031 G stabilizes processing, mitigates cross-linking and gel formulation.

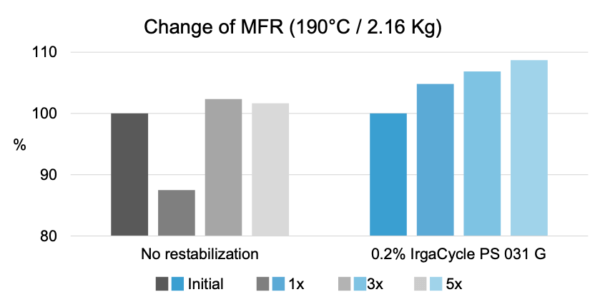

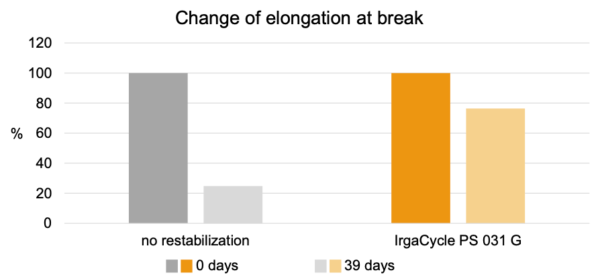

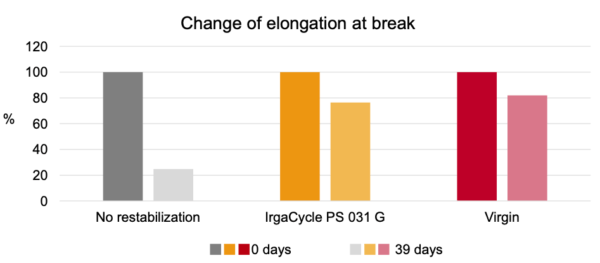

Enhanced Durability of rLDPE

Long-term stability

- rLDPE, extrusion grade

- Post-consumer

- Cast films, 210°C, 50 µm

- Oven aging at 100°C

- Tensile properties 100 mm/min

Tensile properties of recyclate changes significantly upon aging. IrgaCycle™ PS 031 G maintains mechanical properties over whole service life.

Long term stability of recyclates is not sufficient, resulting in mechanical failure over time. IrgaCycle™ PS 031 G upgraded recyclate durability to better match virgin material properties.