For underwater application of grout and concrete, it is important to use additives that allow for good workability, as well as cohesive stabilizing performance. The Azelis labs demonstrated that stabilizing powder additive, Kelco-Crete DG from BASF, results in excellent performance in anti-washout grout and concrete. The cohesive cement paste has been demonstrated to prevent bleeding and maintain the integrity of the cement paste, resulting in high strength development when compared to a mix without Kelco-Crete DG.

Kelco-Crete DG stabilizes the mixture to prevent bleeding and segregation, while achieving good texture and workability with pseudoplastic/shear thinning rheology profile.

See featured video using Kelco-Crete DG in underwater applications

Method

Azelis Construction Solutions Lab used a very simple concrete formulation and added a standard recommended dose of Kelco-Crete DG. This was compared to a control mixture with no anti-washout additive and the two mixtures were subjected to pouring and dipping in clear tap water to demonstrate the cohesiveness of the cement paste when the anti-washout additive Kelco-Crete DG was included.

The videos show the freshly mixed concrete placed in a perforated basket and dipped into a container of clear tap water. In the concrete without the anti-washout additive, the cement paste immediately escapes from the rest of the concrete and spreads throughout the water. When Kelco-Crete DG is in the mixture, there is almost no paste leeching out of the concrete mixture. Afterwards, when the two concrete mixtures are observed side by side, there is far less paste leftover in the control concrete, while the anti-washout additive containing concrete is intact with cohesive paste binding all the aggregate and rock together.

The demonstration with grout shows a similar phenomenon, where pouring control grout into clear tap water shows instant dispersing of the cement into the container of water. In contrast, the grout with anti-washout additive remains cohesive with no dispersing or clouding of the water.

Formulation:

The concrete formulation was a typical simple mixture of rock, sand, and cement. A super plasticizer was added for workability and to reduce the need for excess water in the mixture. Kelco-Crete DG was included in the anti-washout mixture to compare against the control, dosed at 0.64% based on total weight of dry material.

The grout formulation was similar to the concrete mixture, except the aggregates were omitted, resulting a simple paste of cement, super-plasticizer, and Kelco-Crete DG in the anti-washout formulation, dosed at 1.0% based on total dry weight of material.

Performance Results

It was clearly demonstrated that the anti-washout additive significantly reduces bleeding of the cement paste when the concrete or grout is applied underwater.

The photo of the grout in glass jars shows that even after 10 minutes, the water with control grout poured remains cloudy and dirty with an unstable grout mixture settled at the bottom. The jar with anti-washout grout poured in has clear water and a cohesive grout mixture settled at the bottom.

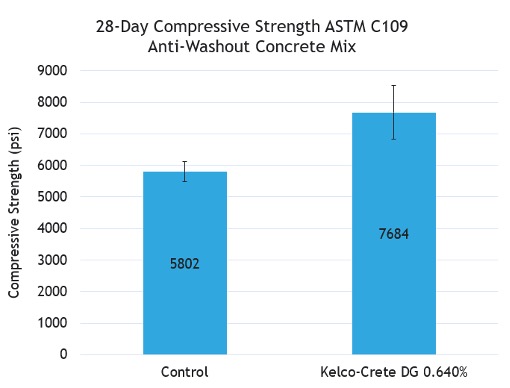

The photos of the water-dipped concrete placed side by side show that with just a short exposure to water, the control concrete lost a great deal of cement and left a lot of aggregate exposed without enough paste to form a cohesive and well-composed concrete, while the anti-washout concrete is much better composed, with all the paste still remaining in the mixture and allowing for a cohesive blend of cement paste, rock, and sand. This is reflected in the strength progression of the two concretes.

Control sample showing exposed aggregate

Using Kelco-Crete DG

The results show that a small amount of anti-washout additive allows for excellent stability and cohesiveness in the concrete and the 28-day strength is significantly better than the control.

Conclusions:

Kelco-Crete DG is an excellent addition to a concrete or grout that needs to be poured underwater. It is an efficient stabilizer that promotes good pouring, pumping, and troweling that also allows for cohesive paste composition.

A very small amount of anti-washout additive is required for a very robust grout or concrete that has excellent strength performance and aggregate distribution, without excess paste being lost to the surrounding water. If pouring the concrete into a shared water source, you can see the reduced potential for harming the environment due to less cement leeching into the surrounding water. Therefore, Kelco-Crete DG can be an economical, as well as an environmentally friendly, solution to underwater construction applications.

The stability provided by Kelco-Crete DG allows for a well-dispersed mixture, reducing segregation and bleeding, while also allowing for excellent workability and pourability. In addition to being an excellent additive for anti-washout concrete for underwater applications, it also works great in other construction applications such as flowable mortars and grouts, pigmented concrete, and self-compacting concrete.

DISCLAIMER - The information contained herein is given in good faith, based on our current knowledge and without any representation and warranty, express or implied, on its quality, accuracy, and completeness. Although it is Azelis’ practice to assist our customers with technical advice and to identify and recommend appropriate solutions for any particular application issue, such assistance, advice, and recommendation is provided without guarantee and warranty, express or implied, in relation to the suitability for use, merchantability or performance of a product, formulation or its individual ingredients for any particular application, and Azelis cannot accept any liability for any possible damages, losses or claims in this respect. Considering that Azelis can neither anticipate nor control the different conditions or circumstances under which the product is being used or commercialized, each user should conduct the necessary research and testing to ensure that a product, formulation, or its individual ingredients are fit for purpose and their intended application and verify whether their use or application does not infringe any third party (intellectual property) rights. Users are responsible for ensuring compliance with applicable laws and regulations when handling any product, formulation, or individual ingredient and are expected to familiarize themselves with the Safety Data Sheet for safety, health, and environmental information, including any instructions related to wearing protective equipment. Where required, users should obtain the necessary certifications, permits, and authorizations prior to using or commercializing any product, formulation, or individual ingredient. Please make certain that you are at all times in possession of the latest version of the written technical specification for each product, formulation, or individual ingredient, which can be requested in writing by mailing to your local representative].