DYTEK A is a multifunctional aliphatic special amine from the company Invista™. This amine is unique in functionality and offers many benefits to formulators.

The popularity and use however, of this very effective amine curing agent & hardener; has been limited due to complaints from formulators (and end-users) that there is a “fishy” or “bad” odor. Our chemists in our Azelis Europe Laboratory targeted a study to see if it is possible to reduce or mask the odor of DYTEK A without losing other (curing) properties.

Method

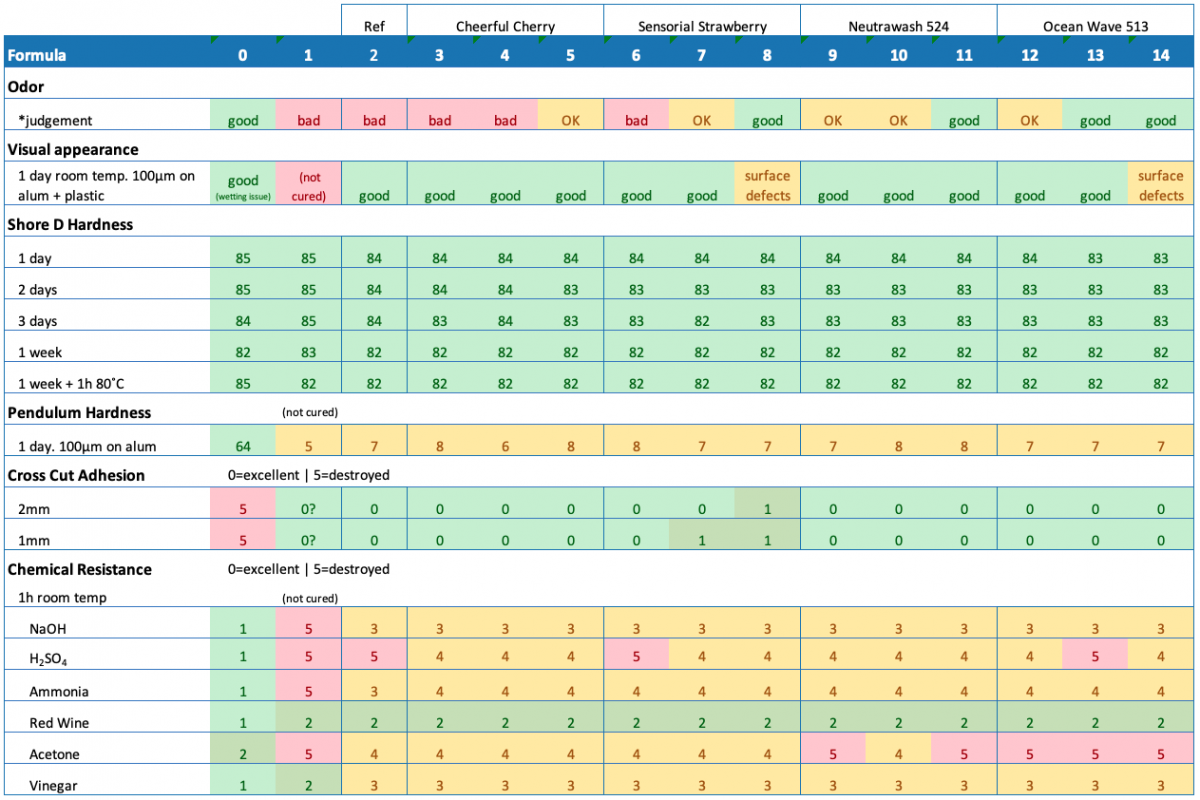

The lab tested four different DPG-based fragrances as listed in the chart below.

- Odor Development: Formulas were judged by multiple chemists in our lab. This odor test is very subjective but was done in good faith with the best objectivity in mind.

- Compatibility: All formulas showed no deposits, no floating, and were storage stable for a minimum of 3 weeks.

Results

Overall, our labs found that the odor of DYTEK A in epoxy systems can be significantly improved with the use of DPG-containing fragrances without significantly impacting performance properties. Some fragrances improved the odor better than others (chart below). The performance is summarized as follows:

Comments

- Visual Appearance: Some surface problems observed with 2 of 14 formulas when applied to black plastic (PA) substrates. Further testing required.

- Hardness: No significant changes in Shore D or Pendulum or hardness.

- Cross-cut Adhesion: No significant decreases in adhesion observed. The reduced adhesion in formulation 7 and 8 could be a result of the surface defects.

- Chemical Resistance: Results are comparable to the reference (formula 2), thus the fragrances had no significant impact on the system.

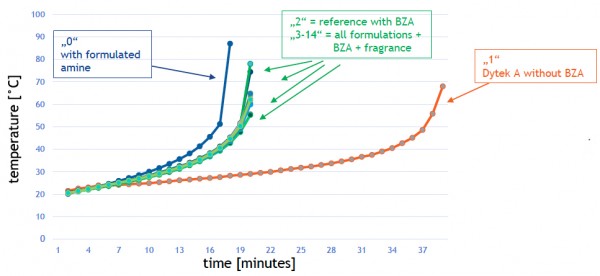

- Curing Speed: After mixing the final epoxy/amine formulation, we took a measurement of temperature development over time as a representation of cure speed. From the graph below (figure 1), it was concluded that the fragrances did not have any measurable impact on cure speed.

Concluding Remarks

Back to our problem statement: is it possible to reduce or mask the odour of DYTEK A without losing other properties? The answer is: Yes, it is possible. We were able to reduce the odor and did not observe any significant impact on

✓ curing speed

✓ visual appearance

✓ Shore D hardness over time

✓ pendulum hardness

✓ cross-cut adhesion

✓ chemical resistance

It is important to note: all of these tests were based on the below assumptions.

- Only one epoxy resin was tested.

- Only one very simple hardener formulation was used (DYTEK A + BZA)

- Tested in controlled lab: 20°C, 50% humidity, no wind, no UV, etc.

- Only a few testers/odor judges used.

These results are only an indication. Formulators are encouraged to test their system in the parameters that are relevant to the end-use application they are creating the product for.

If you are interested in learning more about DYTEK A Amine, talk to your Azelis Sales Representative or try iChat today. Lets get you connected and on the path to your next great product launch!

Innovation through Formulation

DISCLAIMER - The information contained herein is given in good faith, based on our current knowledge and without any representation and warranty, express or implied, on its quality, accuracy, and completeness. Although it is Azelis’ practice to assist our customers with technical advice and to identify and recommend appropriate solutions for any particular application issue, such assistance, advice, and recommendation is provided without guarantee and warranty, express or implied, in relation to the suitability for use, merchantability or performance of a product, formulation or its individual ingredients for any particular application, and Azelis cannot accept any liability for any possible damages, losses or claims in this respect. Considering that Azelis can neither anticipate nor control the different conditions or circumstances under which the product is being used or commercialized, each user should conduct the necessary research and testing to ensure that a product, formulation, or its individual ingredients are fit for purpose and their intended application and verify whether their use or application does not infringe any third party (intellectual property) rights. Users are responsible for ensuring compliance with applicable laws and regulations when handling any product, formulation, or individual ingredient and are expected to familiarize themselves with the Safety Data Sheet for safety, health, and environmental information, including any instructions related to wearing protective equipment. Where required, users should obtain the necessary certifications, permits, and authorizations prior to using or commercializing any product, formulation, or individual ingredient. Please make certain that you are at all times in possession of the latest version of the written technical specification for each product, formulation, or individual ingredient, which can be requested in writing by mailing to your local representative].