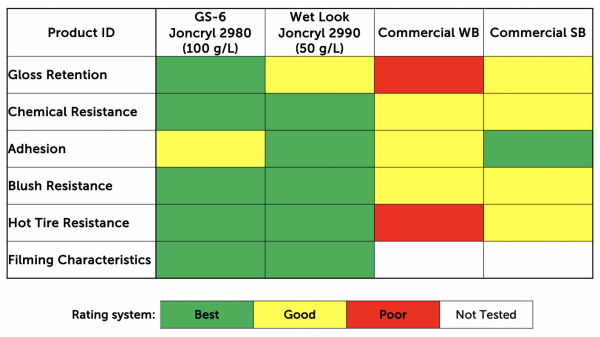

The Azelis CASE Application Lab performed a study to evaluate JONCRYL 2990 in a clear masonry and concrete sealer. The ‘Wet Look’ sealer system is purported to perform as good or better than similar latex and solvent borne systems in the market today. The formulation is only 50 g/l VOC and boasted about having excellent resistance to chemicals and blushing. This formula is suitable for sealing multiple concrete and masonry substrates such as stone, brick, pavers, stamped concrete, and quarry tile. We wanted to put this self-crosslinking acrylic emulsion to the test, generating data for our customers to help them decide if it is the right product for them.

Testing Line-Up:

- JONCRYL 2980 concrete sealer (GS-6); 100 g/l VOC

- JONCRYL 2990 wet-look concrete sealer; 50 g/l VOC*

- Com WB : Commercially available Water Based; 90 g/l VOC

- Com SB : Commercially available Solvent Based

*Tip: This formula is silane fortified with Silquest A-2120 to boost the adhesion performance!

To learn the full formula, processing method, and testing methodology: ask your Azelis Sales Representative or Contact and Expert to receive the full lab report.

Results

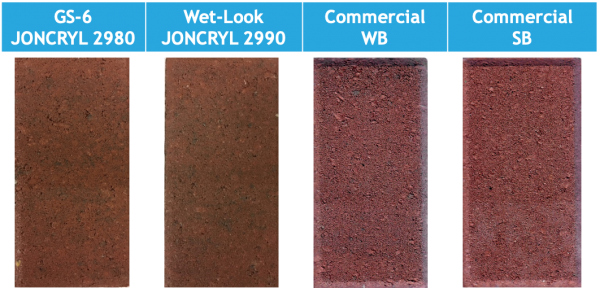

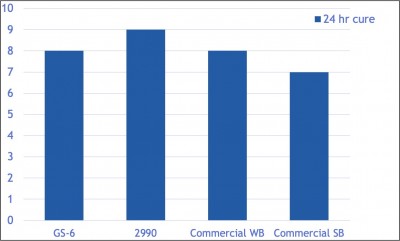

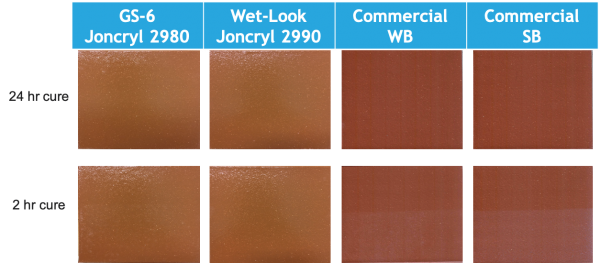

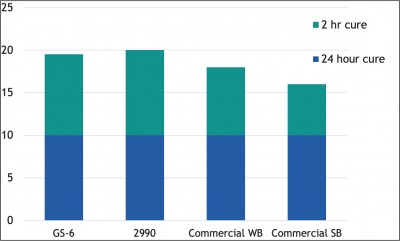

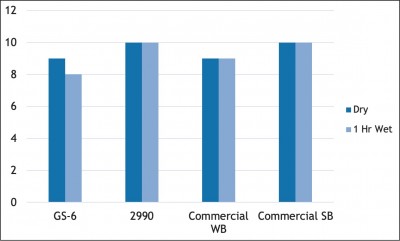

Blushing Test

- Two coats of the sealers were applied to quarry tiles and pavers. They were cured for both 2 and 24 hours at 77°F and 50% relative humidity then immersed in water for 16 hours.

- Tiles and pavers were examined 24 hours after being removed from the water and rated

- Rating scale: 10 = no whitening, no effect on film, 1 = complete film whitening, film degradation

Block Pavers

Quarry Tiles

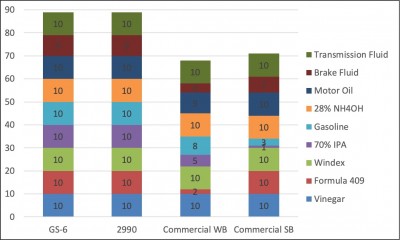

Chemical Resistance Test

- Sealers were applied to quarry tile and allowed to cure for 7 days. Reagents were left on the coatings for one hour.

- Watch glasses and filter papers were removed, tiles were rinsed then dried and each spot was evaluated on a scale from 1-10 where:

- 10 = no film degradation and

- 1 = complete film destruction

Adhesion to Concrete

- ASTM D3359 X-Cut Adhesion, dry and wet

- JONCRYL 2990 had better adhesion to concrete than the commercially available water-based formula

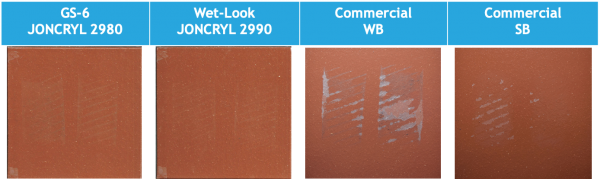

Hot Tire Pick-up

- Test was run on quarry tiles, with a single coat, at 50 PSI for 45 minutes.

- Evaluations are on a 10 (Perfect) to 1 (Complete Failure) Scale

| Property | JONCRYL 2980 (GS-6) | JONCRYL 2990 (Wet-Look) | Commercial WB | Commercial SB |

|---|---|---|---|---|

| Rubber Transfer | 8 | 10 | 7 | 10 |

| Tackiness to Coating | 10 | 8 | 7 | 9 |

| Film Degradation | 10 | 10 | 5 | 7 |

| Overall Change in Appearance | 8 | 9 | 5 | 7 |

Conclusion

JONCRYL 2990 in the Low-VOC “wet-look” concrete and masonry sealer formula outperformed in several categories compared to commercially available wet-look water-based and solvent based formulations. Ask your Azelis Sales Representative or use iChat to receive the full formula and performance document that was used in this Chemist Collaboration.

DISCLAIMER - The information contained herein is given in good faith, based on our current knowledge and without any representation and warranty, express or implied, on its quality, accuracy, and completeness. Although it is Azelis’ practice to assist our customers with technical advice and to identify and recommend appropriate solutions for any particular application issue, such assistance, advice, and recommendation is provided without guarantee and warranty, express or implied, in relation to the suitability for use, merchantability or performance of a product, formulation or its individual ingredients for any particular application, and Azelis cannot accept any liability for any possible damages, losses or claims in this respect. Considering that Azelis can neither anticipate nor control the different conditions or circumstances under which the product is being used or commercialized, each user should conduct the necessary research and testing to ensure that a product, formulation, or its individual ingredients are fit for purpose and their intended application and verify whether their use or application does not infringe any third party (intellectual property) rights. Users are responsible for ensuring compliance with applicable laws and regulations when handling any product, formulation, or individual ingredient and are expected to familiarize themselves with the Safety Data Sheet for safety, health, and environmental information, including any instructions related to wearing protective equipment. Where required, users should obtain the necessary certifications, permits, and authorizations prior to using or commercializing any product, formulation, or individual ingredient. Please make certain that you are at all times in possession of the latest version of the written technical specification for each product, formulation, or individual ingredient, which can be requested in writing by mailing to your local representative].