The tile industry has been steadily moving towards larger tiles for faster installation. The Azelis Laboratory took on a challenge to make a cement tile adhesive (CTA) that could hold a very large and heavy stone veneer tile that needed to be applied vertically with no sag. It also needed to pass the national standard for high performance tile adhesive, ANSI 118.15.

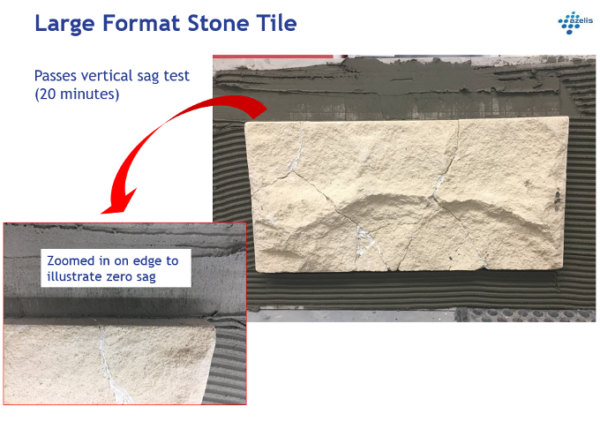

The final mortar formulated by the Azelis Americas Construction Solutions Chemists was smooth and easy to trowel, which is always an important feature for applicators in the field. When the stone veneer tile was subjected to the ANSI sag test, virtually zero sag was observed.

In addition to passing the sag requirement, this mortar also passed all the strength testing requirements in ANSI 118.15, as well as additional compressive strength testing. The CTA had excellent long term workability and open time.

Two key additives helped us achieve the zero sag feature: Starvis® T 50 F and Starvis® RS 421/01 F.

Performance Results

The formulation submitted exceeded all testing requirements.

The stone veneer tile was 30 pounds and approximately 12 x 24 inches in dimension. It was applied it to freshly troweled mortar and held vertically for 20 minutes and measured for distance sagged. The ANSI tolerance is a slim 0.5mm. The original formulation had very poor sag resistance, sliding down the mortar several inches over the course of the 20 minute test. The final formulation developed by Azelis had zero measured sag after 20 minutes, a huge improvement to the original mortar.

| Physical Properties (based on performance of market material provided by customer) | Result |

|---|---|

| Sag (target <0.5mm) | 0.0 mm |

| Open Time (target > 40 min) | ~1 hour |

| Density (Target >1.65 g/cc) | 1.72 |

| 28 day dry shear strength (target >475 psi) | 536 |

| 28 day freeze thaw (target >275 psi) | 328 |

| 28 day compressive strength (target >2400 psi) | 2785 |

Method

Azelis Construction Solutions Lab was tasked to improve upon an existing stone veneer tile adhesive to compete with a competitive mortar currently in the market. The lab needed to match the competitive mortar’s performance in open time, set time, workability, and strength, as well as excellent sag resistant for the heavy and large stone veneer tiles provided.

Formulation

The main challenges were improving sag resistance and texture. Several rheology modifying additives were utilized from the Azelis portfolio to reduce stickiness and provide excellent sag resistance, including starch ether, polyacrylamide, and polyelectrolyte.

Starvis T 50 F is an additive that provides strong sag resistance at very small dosages, in this formulation we added 0.06% Starvis T 50 F.

Starvis RS 421/01 F helps to provide workability, open time, sag resistance, and adhesion. We started testing an existing formulation and removed three ingredients and replaced them with Starvis RS 421/01 F . The original formulation was well designed but was improved with this substitution.

Other enhancements included improved wetout and workability by introducing a fast-acting superplasticizer, which made the mortar a little looser and easier to work with without adding water, as well as improved open time, provided by a higher viscosity cellulose ether. The formulation also incorporated a more compatible redispersible polymer to create stronger bonding.

Open time was improved at 20 minutes and early shear bond strength improved by 20% at a constant water dosage.

A starting point formulation for the Azelis large format tile adhesive is available from your Azelis representative, or can be requested through Chat.

Conclusions

Using Starvis® T 50 F, Starvis® RS 421/01 F and other products from the Azelis portfolio, the latest large format cement tile adhesive not only exceeded the strength testing requirements specified, but passed the challenging sag test on a 30 pound stone veneer tile. The end product was also a user-friendly material that was easy to trowel and work with.

Our additives allowed for an easy to use product that exceeded performance requirements.

Ready to share in our success? Launch your next project with help from the Azelis Americas Chemists! Get innovative solutions to your everyday challenges while maintaining high quality end results.

DISCLAIMER - The information contained herein is given in good faith, based on our current knowledge and without any representation and warranty, express or implied, on its quality, accuracy, and completeness. Although it is Azelis’ practice to assist our customers with technical advice and to identify and recommend appropriate solutions for any particular application issue, such assistance, advice, and recommendation is provided without guarantee and warranty, express or implied, in relation to the suitability for use, merchantability or performance of a product, formulation or its individual ingredients for any particular application, and Azelis cannot accept any liability for any possible damages, losses or claims in this respect. Considering that Azelis can neither anticipate nor control the different conditions or circumstances under which the product is being used or commercialized, each user should conduct the necessary research and testing to ensure that a product, formulation, or its individual ingredients are fit for purpose and their intended application and verify whether their use or application does not infringe any third party (intellectual property) rights. Users are responsible for ensuring compliance with applicable laws and regulations when handling any product, formulation, or individual ingredient and are expected to familiarize themselves with the Safety Data Sheet for safety, health, and environmental information, including any instructions related to wearing protective equipment. Where required, users should obtain the necessary certifications, permits, and authorizations prior to using or commercializing any product, formulation, or individual ingredient. Please make certain that you are at all times in possession of the latest version of the written technical specification for each product, formulation, or individual ingredient, which can be requested in writing by mailing to your local representative].