The Azelis Labs have performed a myriad of tests on BASF Starvis 3040 in order to assess the stabilization benefits that this additive brings to grout/mortar in various applications. Some of the applications include:

Fluid Grout – The application of a fluid grout can be to fill a void, assist with machine mounting, and various other applications. Therefore, the design must be such that the matrix is uniform.

Wind Turbine Grout – Windmill grout/wind turbine grout is used to connect the wind turbine to the concrete foundation. It is a highly pumpable material that has long working times.

Non-shrink Grout – The application of a non-shrink grout can be to fill a void, assist with machine mounting, and various other applications where shrinkage could cause issues with debonding or the creation of voids.

Fluid/Non-Shrink Industrial Grout

Introduction

In cementitious based materials, there are chemical reactions of calcium silicates with water. Often water is added in excess for flow. Unfortunately, this can cause aggregates to settle and make a final material that is not homogeneous which causes inconsistencies in strength. In grout, it is important to be sure the system is fluid to pass speed of flow requirements, but stable to perform. The application of a fluid grout can be to fill a void, assist with machine mounting, and various other applications. Therefore, the design must be such that the matrix is uniform and high strength is achieved. In order to do this, you can first reduce water. Excess water creates an open structure and reduces strength. However, this grout must be fluid so reducing water is difficult. In order to maintain a high flow with minimal water, plasticizers or water reducers must be included. This will allow the grout to flow yet reduce the water to maximize strength. The design must also include a stabilizer so the sand in the system is held evenly through the casting. In this application a thixotropic stabilizer is ideal. This will allow the material to flow well while mixing and pouring and then hold the aggregates and fillers evenly as soon as shear forces are stopped.

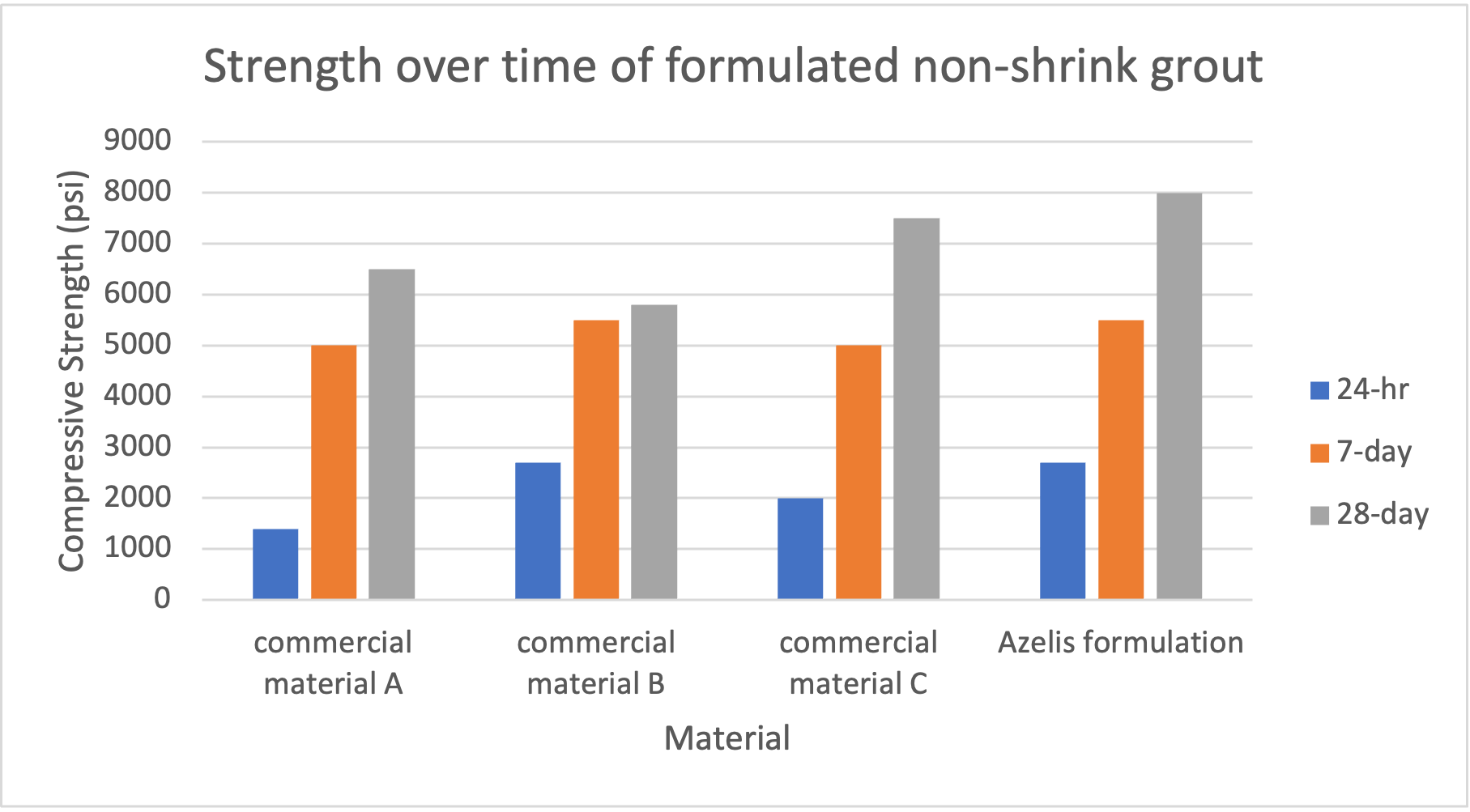

The Azelis laboratory was approached to develop a formulation for a non-shrink grout that competes with existing products on the market; test results of the new formulation are shown below:

Compressive Strength of Azelis Formulation Compared to Other Market Products

Results

This formulation hit other key performance parameters like achieving a volume change of 0.15%. It also had an initial flow of 25 sec and maintained a flow of about 30 seconds after 30 minutes using the standard flow cone from ASTM C 939. These were all accomplished from our in-house formulation which utilized Starvis 3040 for proper flow and stability to maintain a homogeneous final product.

Starvis 3040 is a water-soluble high molecular weight polymer in powder form with inorganic anticaking agent. It acts as a viscosity-enhancing agent (with thixotropic rheology profile) to prevent bleeding and segregation.

Wind Turbine Grout

Introduction

Windmill grout / wind turbine grout is used to connect the wind turbine to the concrete foundation. It is a highly pumpable material that has long working times. It is ultimately a high strength material that must perform in adverse conditions for on-shore and off-shore applications. We have three key ingredients for this which includes the superplasticizer/water reducing agent, stabilizer, and defoamer. The stabilizer is particularly important to help the material flow well and maintain a uniform matrix.

Formulation

The formulation requires a strong plasticizer. It must be effective in keeping the water as low as possible. It must also assist with longevity in pumpability. The formulation must be designed to remove any air to increase the density and strength of the cement matrix. Stability is also vital. Since the fliud material is often pumped, holding the fillers and additives in an even distribution until setting occurs, can be difficult. Therefore stability additives must be included.

Conclusions

The Azelis lab has formulated with the Starvis 3040 additive in various construction applications and successfully formulated these materials with enhanced properties to fit these specific needs:

- A high strength grout with good non-shrink characteristics

- A high strength grout with suitable flow characteristics

- Grouts that have excellent stability in applications that need to be poured underwater and/or used in on-shore and off-shore applications

Overall, the stability provided by Starvis 3040 allows for a well-dispersed mixture, reducing segregation and bleeding, while also allowing for excellent workability and pourability. In addition to being an excellent additive for grouts, it also works great in other construction applications such as flowable mortars, pumpable materials, and self-compacting concrete.

DISCLAIMER - The information contained herein is given in good faith, based on our current knowledge and without any representation and warranty, express or implied, on its quality, accuracy, and completeness. Although it is Azelis’ practice to assist our customers with technical advice and to identify and recommend appropriate solutions for any particular application issue, such assistance, advice, and recommendation is provided without guarantee and warranty, express or implied, in relation to the suitability for use, merchantability or performance of a product, formulation or its individual ingredients for any particular application, and Azelis cannot accept any liability for any possible damages, losses or claims in this respect. Considering that Azelis can neither anticipate nor control the different conditions or circumstances under which the product is being used or commercialized, each user should conduct the necessary research and testing to ensure that a product, formulation, or its individual ingredients are fit for purpose and their intended application and verify whether their use or application does not infringe any third party (intellectual property) rights. Users are responsible for ensuring compliance with applicable laws and regulations when handling any product, formulation, or individual ingredient and are expected to familiarize themselves with the Safety Data Sheet for safety, health, and environmental information, including any instructions related to wearing protective equipment. Where required, users should obtain the necessary certifications, permits, and authorizations prior to using or commercializing any product, formulation, or individual ingredient. Please make certain that you are at all times in possession of the latest version of the written technical specification for each product, formulation, or individual ingredient, which can be requested in writing by mailing to your local representative].