A robust air entrainer is essential in cementitious materials. In stuccos and renders, it is needed to maintain a constant volume without deflating and reducing yield. It is also essential for workability and troweling. In concrete and repair, a precise amount of entrained air is needed for freeze thaw durability and crack prevention without compromising strength by entraining too much air. Some of the benefits of using air entrainers include:

- Maintaining constant volume

- Better workability and troweling

- Freeze-thaw durability and crack prevention

Azelis Construction Solutions Lab has been tasked repeatedly to develop formulations to improve properties of cement and concrete products. Recently the Azelis laboratory conducted a study to determine how well various air entrainers stabilize the air system in a concrete material. Air stability is important for concrete durability and therefore, this could be used in a variety of markets. Specifically, BASF’s Vinapor AE 3914 was tested on a simple masonry mortar and was tested comparatively with additional air entrainers.

- Determine how well various air entrainers stabilize the air system in a concrete material

- Test the product on a simple masonry mortar initially

- Test comparatively with additional air entrainers

Testing Parameters

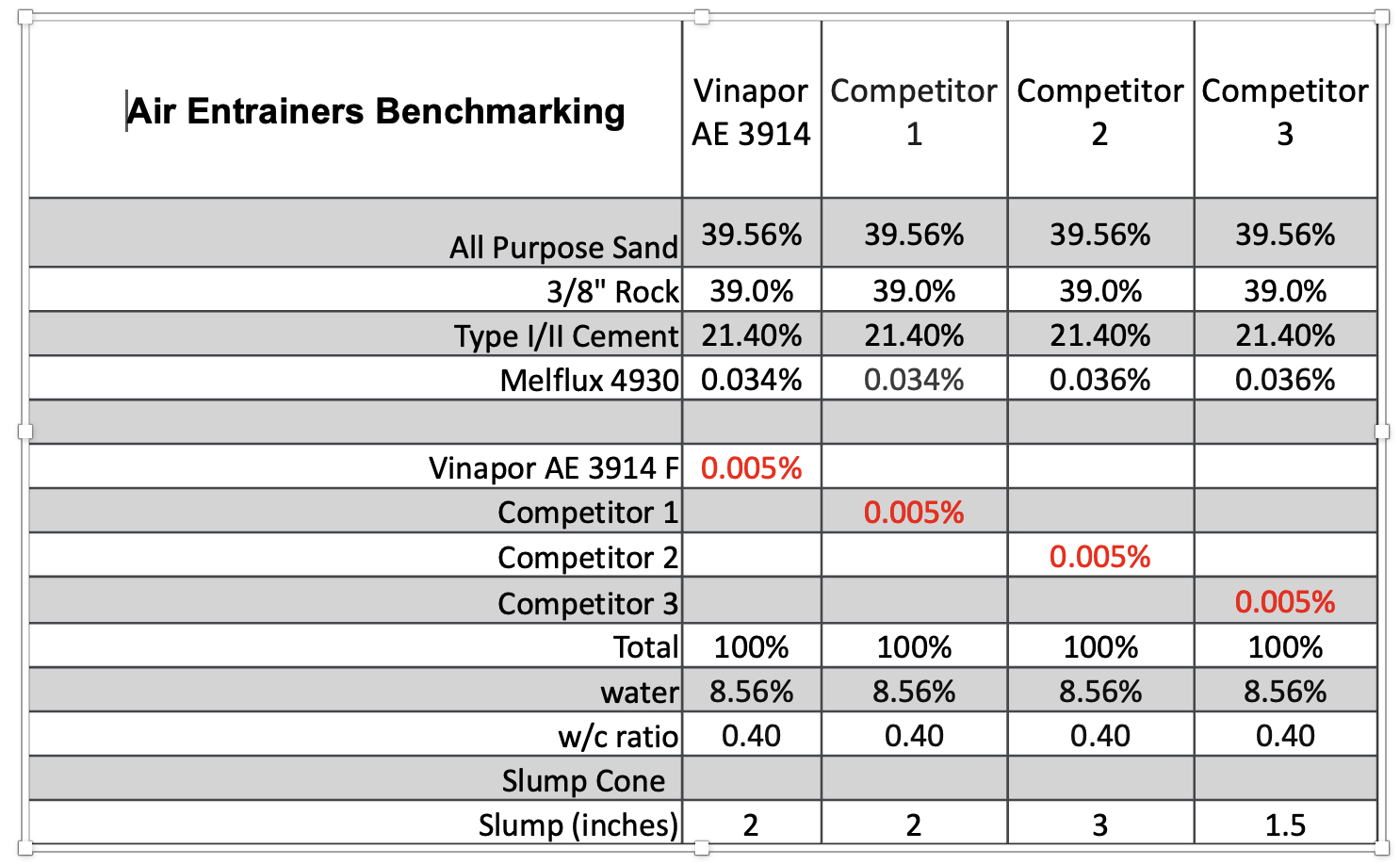

This benchmarking study used a simple concrete formulation.

The mixes were measured for density immediately after mixing with a drill for 3 minutes.

The mixes used various doses of water, Melflux 4930, and Vinapor AE 3914 in these proportions:

Density – ASTM C185

400 mL brass density cup

- 3 lifts

- 20 tamps per lift with rubber tamp

- 5 taps with rubber mallet per lift

Test Results

Correlation between density and air content by air meter measures

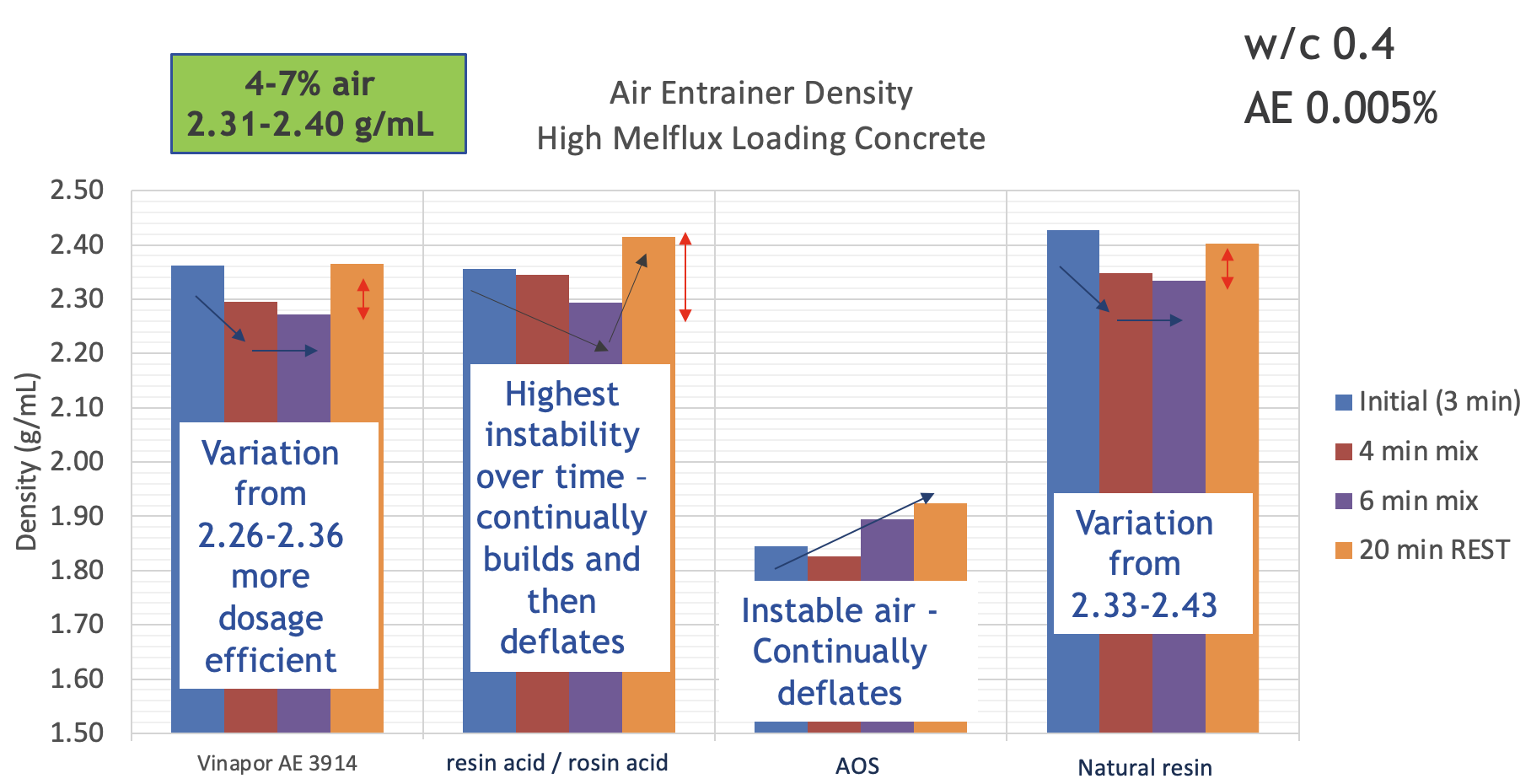

Based on several air content measurements using a standard air meter, it was determined that the optimum range of 4-7% air corresponds to density measurements of 2.33-2.41 g/cm^3. Typically the concrete industry uses one or both of these measurements to determine air content, so this provides a reference of correlation.

Test Results – Various Air Entrainers

Four different air entrainer chemistries were trialed at the same dosage of 0.005% on total dry. Each chemistry was tested for robustness by subjecting the concrete to various mixing times and prolonged resting periods.

Vinapor AE 3914 shows minimal variation, staying between 2.26-2.36 g/cm^3. The competitive resin acid/rosin acid shows a lot more instability, continually building air with prolonged mixing, and then deflating when resting. The competitive alpha olefin sulfonate (AOS) is unable to reach the target air range, and the mix continued to deflate, showing the greatest instability of air. Finally, the competitive natural resin, a well established and popular market product, shows similar stability as the Vinapor AE 3914, but the density is higher, showing the dosage efficiency of Vinapor AE 3914 – it is able to entrain more air than the natural resin at the same dosage.

Vinapor AE 3914

Vinapor AE 3914 works as a stable air entrainer that can withstand aggressive mixing and long resting periods. It is very dosage efficient so only a small amount is needed to achieve stable air entrainment. It has also been shown to perform well in concrete mixes. Even with large aggregate and variable mixing equipment, customer concrete formulations have been shown to successfully achieve 6-8% air consistently.

DISCLAIMER - The information contained herein is given in good faith, based on our current knowledge and without any representation and warranty, express or implied, on its quality, accuracy, and completeness. Although it is Azelis’ practice to assist our customers with technical advice and to identify and recommend appropriate solutions for any particular application issue, such assistance, advice, and recommendation is provided without guarantee and warranty, express or implied, in relation to the suitability for use, merchantability or performance of a product, formulation or its individual ingredients for any particular application, and Azelis cannot accept any liability for any possible damages, losses or claims in this respect. Considering that Azelis can neither anticipate nor control the different conditions or circumstances under which the product is being used or commercialized, each user should conduct the necessary research and testing to ensure that a product, formulation, or its individual ingredients are fit for purpose and their intended application and verify whether their use or application does not infringe any third party (intellectual property) rights. Users are responsible for ensuring compliance with applicable laws and regulations when handling any product, formulation, or individual ingredient and are expected to familiarize themselves with the Safety Data Sheet for safety, health, and environmental information, including any instructions related to wearing protective equipment. Where required, users should obtain the necessary certifications, permits, and authorizations prior to using or commercializing any product, formulation, or individual ingredient. Please make certain that you are at all times in possession of the latest version of the written technical specification for each product, formulation, or individual ingredient, which can be requested in writing by mailing to your local representative].