The polyurethane foam market continues to innovate, diversify, and grow into new end-use applications. From high-volume to high-performance materials; the adaptability, durability, and performance of polyurethane chemistry for rigid, molded and slab-stock foam, has allowed designers and manufacturers to meet performance challenges and efficiencies that previously couldn’t be met.

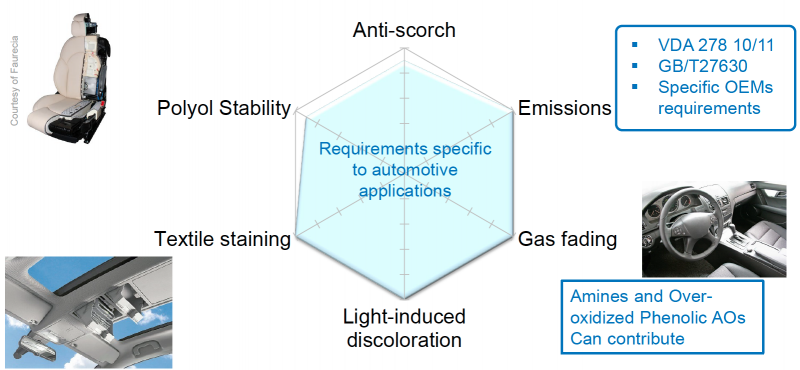

Government regulations and the automotive industry are clearly increasing the needs for more sustainable materials to be used in car interiors. The quality of air in car interior has been a continuously evolving topic to improve health and safety of car passengers. The automotive industry has given additional emphasis to the volatile component emissions of the final article.

Improving the performance, health, and safety of polymers for automotive applications has been an innovation driver that has benefited so many industries and applications. As a formulator, you now have options for stabilizer packages that can be optimized for your performance requirements and costs. Which package has the right balance of properties for your application?

| Anti-Scorch Package | SCORCH | TEXTILE STAINING | GAS FADE | LIGHT STABILITY | FOGGING | PRODUCT FORM |

|---|---|---|---|---|---|---|

| IRGANOX 5057 (BHT) | Good | Poor | Poor | Poor | Poor | Poor |

| IRGANOX 1135 / IRGANOX 5057 | Very Good | Good | Poor | Poor | Medium | Very Good |

| IRGANOX 1076 / IRGANOX 5057 | Very Good | Good | Poor | Poor | Good | Medium |

| IRGASTAB PUR 67 | Very Good | Very Good | Good | Good | Good | Very Good |

| IRGASTAB PUR 70 | Good | Excellent | Excellent | Excellent | Excellent | Very Good |

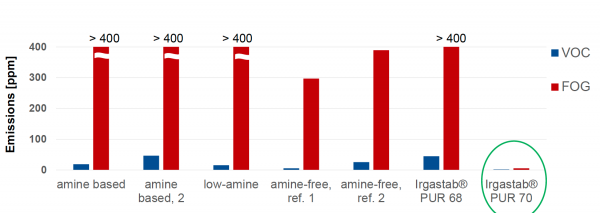

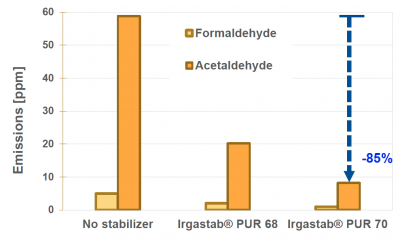

IRGASTAB PUR 70 is a novel anti-scorch additive that provides extremely low emissions and reduces significantly the aldehyde emissions in Polyol and PUR foams. This addresses the increasing challenge to meet emissions requirements of the automotive industry as well as in the furniture and bedding industry. Due to its outstanding gas fading resistance and light-induced discoloration IRGASTAB PUR 70 can be used in applications outside automotive where foam whiteness is key.

IRGASTAB PUR 70 Performance

Negligible contribution to emissions & fog

Foam emissions VDA 278 10/11

Reduces aldehyde emissions in Polyol

AO Loading 0.1%. Aged at 100˚C for 48 hours.

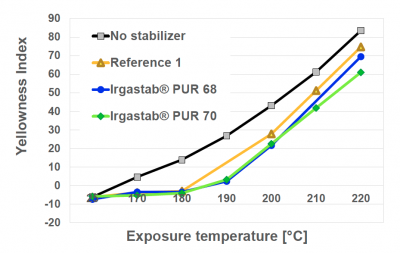

Anti-scorch performance in PU foams

Low density foam (6-20 kg/m3). AO loading: 0.45%.

.

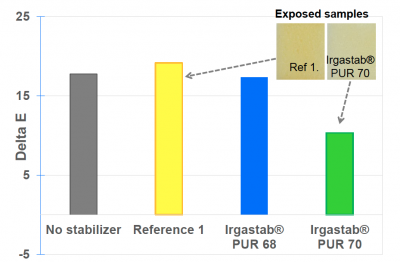

Superior gas fading resistance

*Gas fade chamber @40˚C, 65% RH, 4-6 ppm NOx content. AO Loading 0.45%.

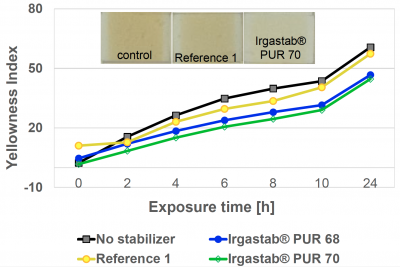

Extremely low discoloration

AO Loading 0.45%.

IRGASTAB PUR 67 is a liquid heat stabilizer blend for polyether- and poly-ester-based flexible foams. It is a cost-effective low amine synergistic antioxidant blend for use in low and medium density slab foams where reduced emissions are required.

Have Questions? We’re here to help!