Looking to make an antimicrobial surface claim for your paint or building material, but don’t understand if you need to register?

The use of biocides in coatings and construction materials, has been known to formulators since the creation of the first waterborne paint. The need to prevent these products from becoming a breeding ground for microbes in their packaging was quickly realized. With years of research (and trial-and-error), the industry is well educated on the efficiencies, the risks, and the resulting regulatory and labeling requirements of biocides for in-can protection.

The next generation of antimicrobial additives however, are not only focused on protecting formulations in-the-can, but on the dried surface long after its application. There are many commercialized products with biocides for antifouling (a.k.a. mold build-up), but with heightened public health concerns for contaminated surfaces, the industry is asking: what else can an antimicrobial do? Can we make surfaces safer for the greater good of public health? What are the needs, what are the risks, and… what are the regulations?

Is it a Biocide, a Fungicide, a Pesticide, or…?

In the USA: the biocides, fungicides, algicides, and antimicrobials commonly used in coatings and construction materials, all fall under the definition of a pesticide and are thus heavily regulated by the US EPA for their quantities, end-use applications, and labeling.

Pesticide active ingredients are described by the types of pests they control or how they work. See the EPA’s definitions of Types of Pesticides to help understand the defined classifications for biocides, antimicrobials, fungicides, and other common materials used to protect coatings and building materials.

So What is an Antimicrobial Pesticide?

An “antimicrobial pesticide” is defined in section 2(mm) of FIFRA as a pesticide that is intended to: disinfect, sanitize, reduce, or mitigate growth or development of microbiological organisms; or protect inanimate objects, industrial processes or systems, surfaces, water, or other chemical substances from contamination, fouling, or deterioration caused by bacteria, viruses, fungi, protozoa, algae, or slime; and is exempt from or not subject to a tolerance…or a food additive regulation.

What is the “Treated Article Exemption” and Would my Product Qualify?

Treated Article Exemption

= Non-Public Health Claim

A Treated Article Exemption can help companies avoid the EPA pesticide registration as long as you are making a non-public health claim. The Treated Article Exemption in 40 CFR 152.25(a) “covers qualifying treated articles and substances bearing claims to protect the article or substance itself”. Here are some examples of acceptable product claims:

Inhibits the growth of mildew on the surface of a dried paint film or paint coating

Inhibits microorganisms which may cause spoilage or fouling of the treated article or substance

Inhibits offensive odors in the treated article or substance

You can still use terms such as “antimicrobial,” “fungistatic,” “mildew- resistant,” and “preservative,” provided that they are properly, and very clearly, qualified as intended for non-public health use.

If your Claim says This

= Registration as a Pesticide

- Antibacterial

- Bactericidal

- Germicidal

- Kills pathogenic bacteria

- Effective against E. coli and Staphylococcus

- Reduces the risk of food-borne illness from bacteria

- Provides a germ-resistant surface

- Provides a bacteria-resistant surface

- Surface kills common gram positive and negative bacteria

- Surface controls both gram positive and negative bacteria

- Surface minimizes the growth of both gram positive and negative bacteria

- Reduces risk of cross-contamination from bacteria

- Controls allergy causing microorganisms

- Improves indoor air quality through the reduction of microorganisms

What Tests do I Need to Make for an Antimicrobial Claim?

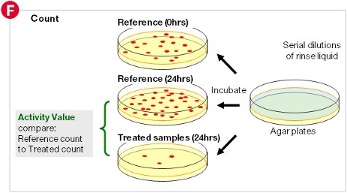

JIS Z 2801

This method is the most commonly chosen test and has become the industry standard for antimicrobial hard surface performance in the United States.

The JIS Z 2801 method tests the ability of plastics, metals, ceramics, coatings and other antimicrobial surfaces to inhibit the growth of microorganisms or kill them. The procedure is very sensitive to antimicrobial activity and has a number of real world applications anywhere from the hospital/clinical environment to a household consumer company concerned with the ability of a material they have to allow bacterial growth.

The JIS Z 2801 can be modified for VIRUS – Contact us to learn how!

ASTM G 21 Fungal Test

The ASTM G 21 method, titled “Standard Practice for Determining Resistance of Synthetic Polymeric Materials to Fungi” is designed to test the resistance of synthetic polymeric materials (molded materials, surface treated articles or similar objects) to fungal attack.

Think you need this test? Contact us for more information

Antimicrobial Performance Additives

Innovation through Formulation – Let’s Make it!

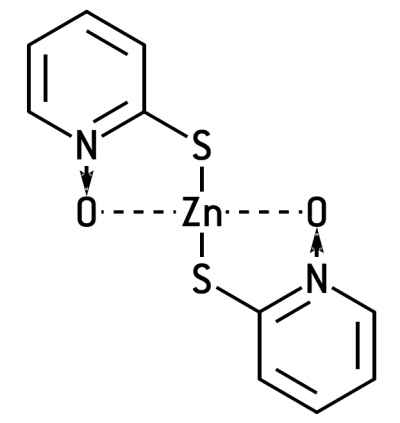

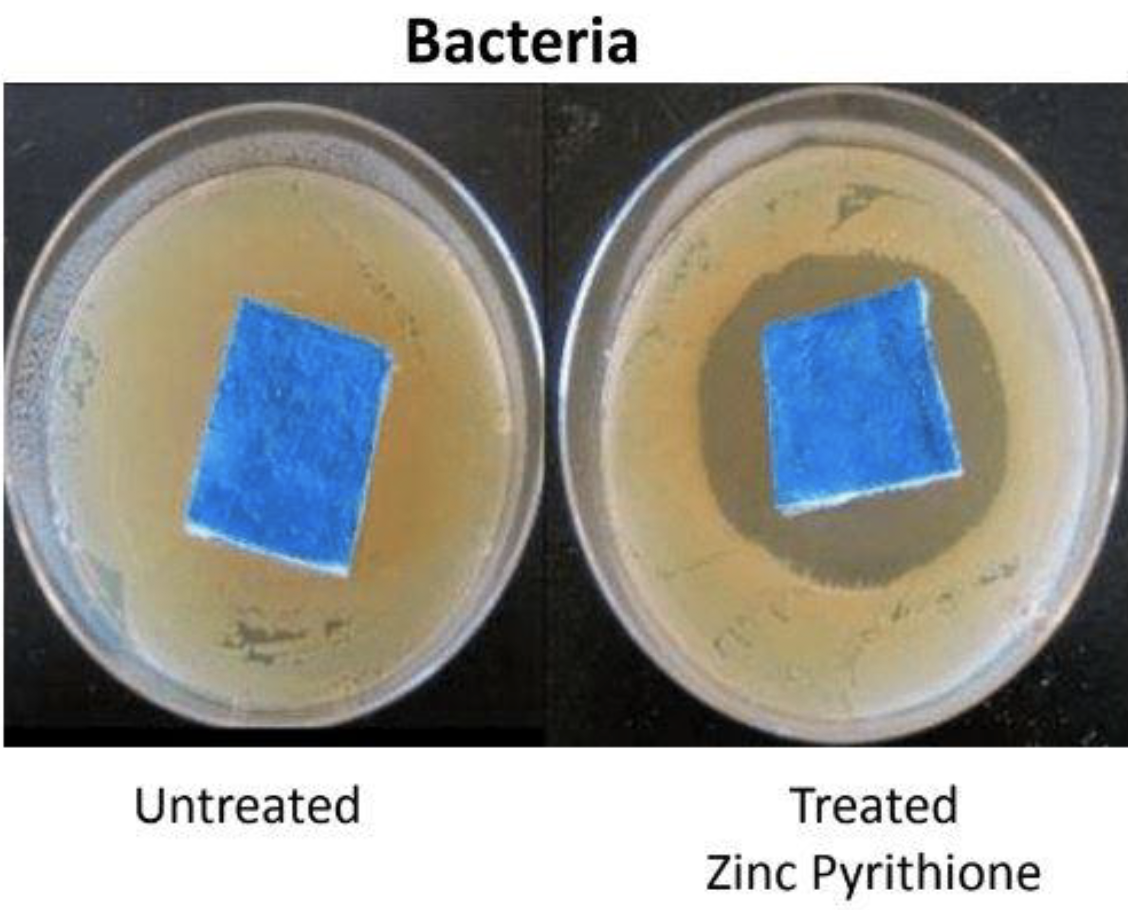

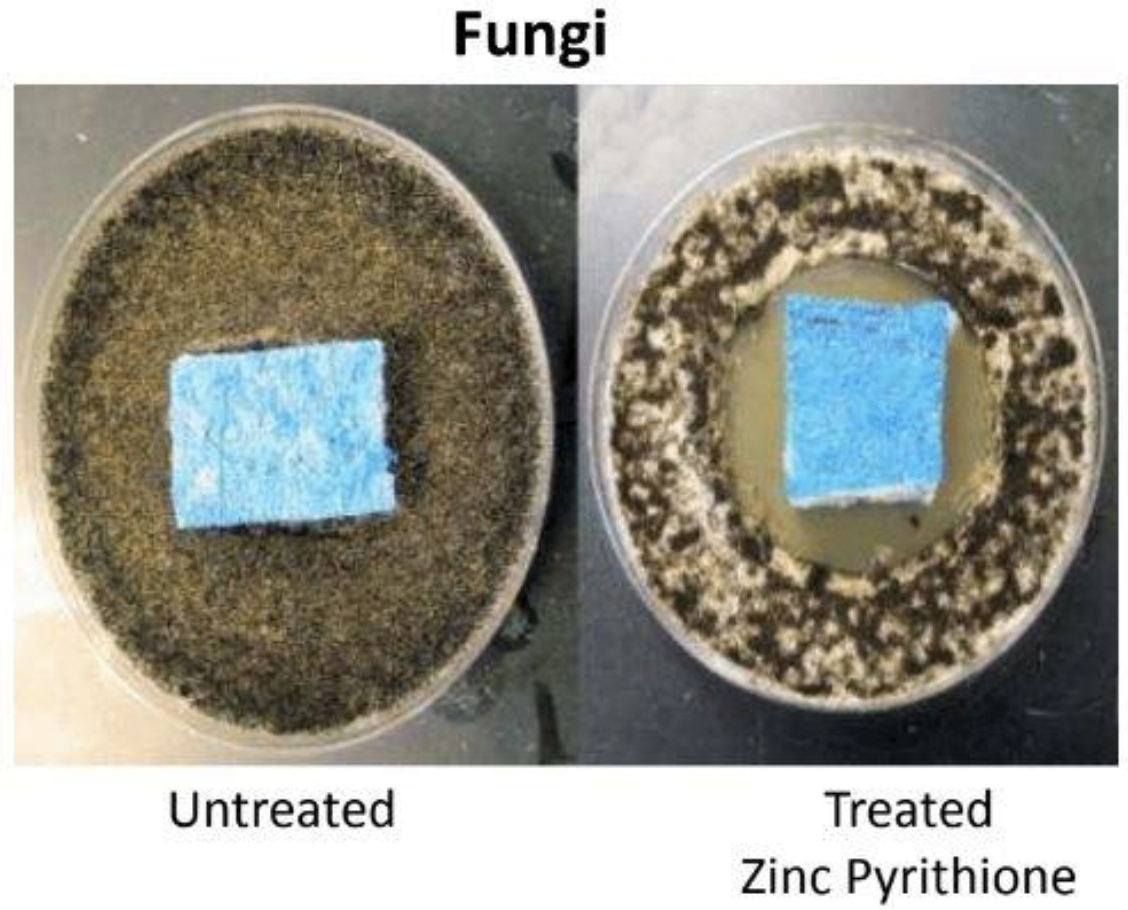

Zinc OMADINE ZOE Antimicrobial

Zinc pyrithione dispersion

Zinc Omadine ZOE® Antimicrobial is an effective broad-spectrum mildewcide-algicide for the dry-film preservation of industrial products. This fine particle dispersion is specially formulated to not discolor due to interactions with various elements that can be present in some industrial formulations.

Typical dosage as a dry film preservative for coatings and building products: 0.025%-1.2%

Features & Benefits

- Broad spectrum antimicrobial

- Low water and plasticizer solubility

- Active not based on arsenic or tin

- No VOCs, low odor, pumpable and color stable dispersion

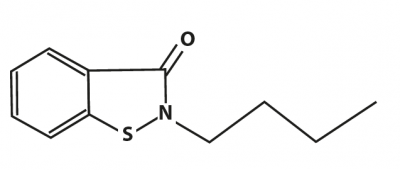

Densil DN Antimicrobial

N-butyl-1,2-benzisothiazolin-3-one (BBIT)

Densil® DN Antimicrobial is a broad spectrum fungicide, bactericide and algaecide based on BBIT. Densil DN Antimicrobial can be used to prevent microbial degradation of various building construction materials in different application areas, to offer dry film and wet state preservation.

Need More Ideas for your Project?

Problem to Solve > Microbial Growth

- Key Raw Materials

- Starting Point Formulas

- Chemist Collaboration

Have Questions? We’re here to help!