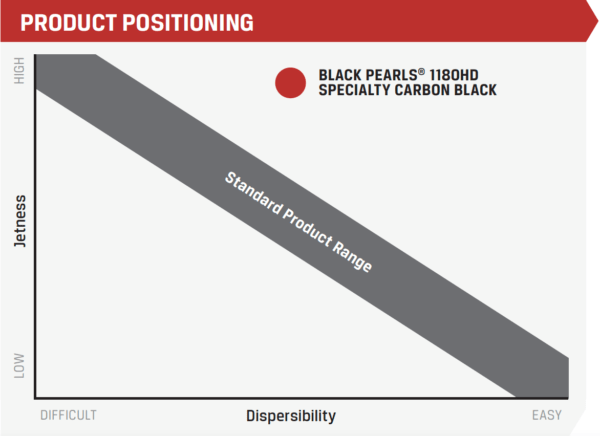

Compounders of high performance thermoplastics and engineered thermoplastics used in automotive parts, electrical and electronic components, household appliances and other industrial applications face challenges in their use of pigments. These challenges include: tradeoffs between color performance and dispersibily, loss of mechanical strength, and achieving desired jetness of black color. Fortunately, solutions exist for these challenges with a new specialty carbon black pigment!

BLACK PEARLS® 1180HD Specialty Carbon Black

Performance Improvement

- Allows users to eliminate the tradeoff between color performance and dispersibility

- Reduces the loss of mechanical strength thanks to reduced loadings and better dispersion, enabling dark black plastic compounds to retain unmatched combinations of color, impact and tensile behavior

Resin Flexibility/Cost Savings

- Enables compounders to increase the share of post-industrial and/or post-consumer recycled feedstock in their formulations due to retention of mechanical strength

- Higher content of recycled feedstock reduces raw material cost of formulations

Enhancing Sustainability

- Higher retention of mechanical properties enables metal replacement and thinner walls molding to meet lightweighting needs and meeting CO2 emission reduction targets

- Increased usage of recycled feedstock supports a circular economy, creating more sustainable products and reducing the reliance on fossil raw material input

Key Applications

- Automotive parts (interior, exterior, under-the-hood) with high mechanical strength requirements

- Electrical engineering & electronics parts (E&E)

- Household appliances

- Industrial and other technical applications

Have Questions? We’re here to help!