The recycled plastics industry has been tasked to achieve ambitious new goals in order to meet society’s demands for a circular economy. These goals have driven increased demands for recyclate to meet recycled content targets desired by both rigid container manufacturers and end-use customers. Not only are volume requirements higher, but customers expect the quality of the recycled material to have similar mechanical properties of original (virgin) material. To help recycled plastics suppliers meet these enhanced requirements, additives have been developed that meet these needs!

IrgaCycle™ Additive Solutions are Specifically Designed to Boost the Quality and Quantity of Recycled Content in Plastic Products!

These solutions, tailored to various industries and diverse polymer streams, enable plastics to be used more than once in high-performance applications. IrgaCycle™ additive solutions protect recyclates during processing and beyond. Enhancing recyclates for packaging, automotive, and agriculture applications ensures that plastics are used sustainably and diverted from landfills as one solution to create a circular economy.

Performance Benefits of the IrgaCycle Line:

- Improves quality and durability of rigid products made from post-consumer and post-recyclable recycles

- Enhances processing and long-term stability

- Tailored for strongly degraded or contaminated rHDPE and PP

- Granular form is dust-free for easy dosing during processing

- Improves melt flow rates of recycled plastics

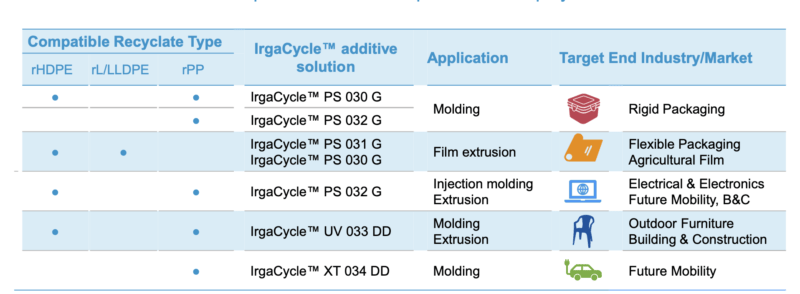

IrgaCycle™ Portfolio Overview

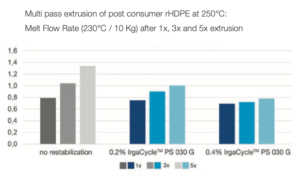

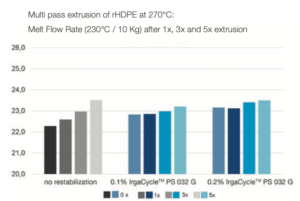

BASF IrgaCycle™ 030 G and 032 G

Increase Quality of Recyclates for Rigid Containers

IrgaCycle™ PS 030 G is an additive composition of stabilizers to improve the durability of rigid articles made with polyolefin recyclates. This product is designed specifically for re-stabilization of post-consumer and post-industrial rigid polyolefin recyclates during re-granulation or conversion steps. The product enhances the processing and long-term stability of recycled plastics. It is especially suited for HDPE and PP recyclates sourced from bottles, caps, containers, crates, bins, or PP and HDPE scrap films.

IrgaCycle™ PS 032 G is an additive composition of stabilizers to improve processing and long-term thermal stability of recycled polyolefin recyclates, that show heavy degradation or were the initial plastic was exposed to aggressive substances like acids. This ingredient is tailored for strongly degraded recycled PP and HDPE materials, e.g., from long term applications or materials with exposure to aggressive substances like acids (e.g., battery cases). It is suitable for addition into re-granulation or conversion steps.

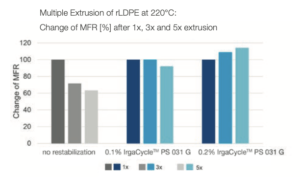

IrgaCycle™ PS 031 G

Sustainable Processing of Recyclate for Films and Flexible Packaging

IrgaCycle™ PS 031 G is a stabilizer and co-additive to increase the content of recycled polymers in polyolefin film applications. This product is designed specifically for re-stabilization of post-consumer and post-industrial polyolefin-films during re-granulation or conversion steps. The product enhances the processing and long-term stability of the recycled plastics. It is especially suited for recycled LDPE and LLDPE; e.g. recycling streams originating from packaging films, wrap or shrink films, or other flexible packaging forms.

Performance Highlights

- Enhances processing of rLDPE and rLLDPE

- Improves the melt flow rate of rLDPE and rLLDPE

- Limits gel formation in flexible applications

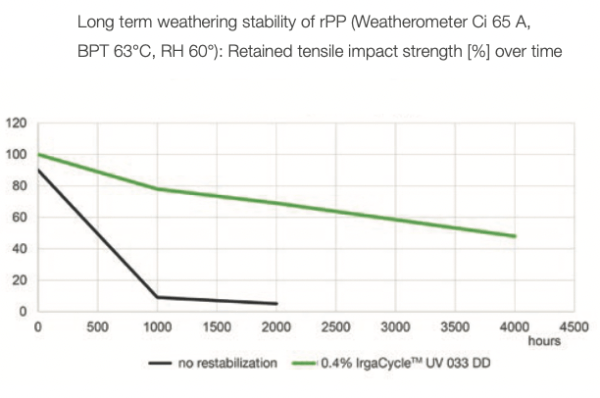

IrgaCycle™ UV 033 DD

Enhance Recyclate Quality for Durable Plastics

IrgaCycle™ UV 033 DD is an additive composition of various stabilizer systems to improve durability and weathering properties of recycled polyolefins. This product can be used to upgrade recycled material originating from short-life applications (such as packaging) for re-use in long-term applications and higher value applications. It is tailored for recycled LDPE, LLDPE, HDPE and PP for use in thick section articles such as bottle crates, containers, waste bins or pallets, for use in durable and outdoor applications.

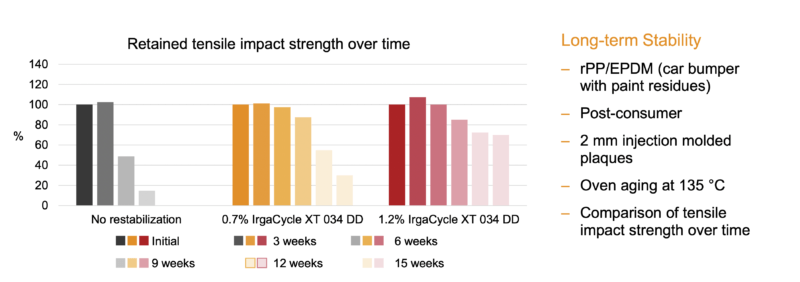

IrgaCycle™ XT 034 DD

Improve Processing of Highly Contaminated Recyclates.

IrgaCycle™ XT 034 DD is an additive composition of stabilizers designed improve processing of highly contaminated recyclates. This product is tailored for post-consumer and post-industrial polyolefin recyclates, which contain high amounts of incompatible contaminants. It is also well suited for PP/EPDM regrinds contaminated with paint residues (e.g. TPO bumper scrap) or Polycarbonate (PC)/polyester blends contaminated with paint residues (e.g. PC/PBT bumper scrap).

Performance Highlights

- Neutralizes residual paint particles, fillers, and carbon black to enable better processability and reduce undesired side reactions

- Provides stable melt flow properties, enhanced long-term thermal stability for improved mechanical properties

- Upgrades recyclates from automotive applications for reintegration into initial applications

- Easy to handle product form allows easy doasing at various processing steps

- Enhances processing and long-term stability of strongly contaminated recycled HDPE and PP fractions (source: highly filled, pigments, and coated materials such as automotive bumpers)

Enhances Process Stability of Contaminated rPP/PDM

Have Questions? We’re here to help!