ACRONAL PRO 770 NA

ACRONAL PRO 770 NA

ACRONAL® PRO 770 NA is an acrylic emulsion polymer that can be used universally to formulate waterborne direct to metal (DTM) paints and anti-corrosive primers. It shows excellent adhesion to metal substrates. ACRONAL PRO 770 NA reduces application time and saves on formulation complexity by eliminating the need for corrosion inhibitors and active pigments.

This product shows outstanding anti-corrosive properties both in glossy DTM and matte monocoat/primer applications without or with only limited addition of phosphate anti-corrosive pigments. It is APEO- and zinc-free in a waterborne formula, combining best-in-class corrosion protection with environmental benefits.

Target applications for ACRONAL PRO 770 NA:

- Building exteriors in highly industrial areas and/or coastal regions

- Building interiors for food manufacturers, breweries, and dairies

- Steel construction parts

- Exterior tanks

Features & Benefits

- Zinc and APEO free

- Superior corrosion resistance in DTM formulations for C2 – C3 applications

- Good adhesion to metal substrates

- Excellent application properties (airless spray, dip coating, etc.)

- Excellent outdoor durability

- Good pigment wetting: can be used as grind vehicle

- Excellent protection achieved by zinc-free formulations or with low zinc content

- Saves formulation cost: no need for corrosion inhibitors

- Self-crosslinking and low VOC capable

For more information on ACRONAL PRO 770 NA, check out the Product Value Card!

Performance Data

More than 20 DTM resins were tested in the following benchmarking study. The result?: ACRONAL PRO 770 outperformed or matched best-in-class performance against competitive resins!

See the Formula: Monocoat WB Acrylic DTM – APEO-and zinc-free – White

Highlights

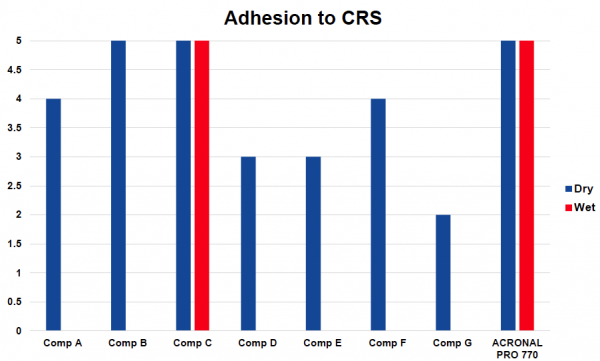

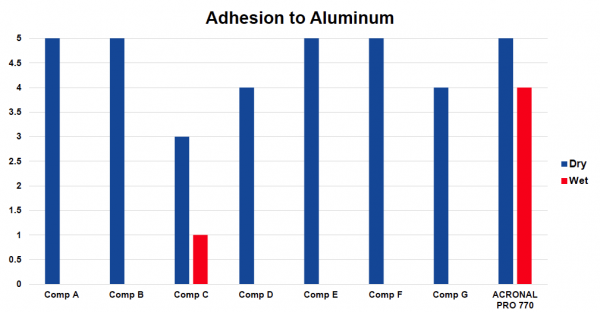

Adhesion Testing: ASTM D3359 (B)

Figure 1: ACRONAL PRO 770 offers best-in-class wet and dry Dry and Wet CRS adhesion.

Figure 2: ACRONAL PRO 770 is the only resin to show good wet adhesion to aluminum.

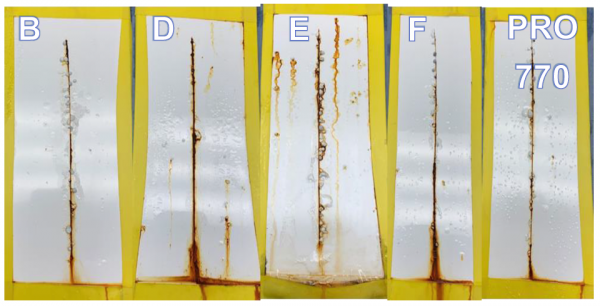

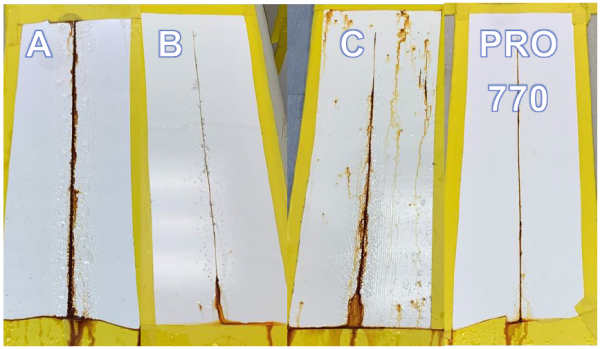

Corrosion resistance: ASTM B-117

Figure 3: 48 hours of ASTM B-117 testing. (Only top performing resins B and ACRONAL PRO 770 continued in Figure 4)

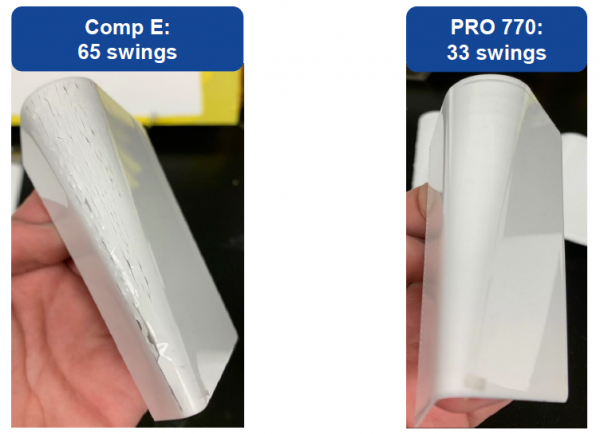

Flexibility: ASTM D552

Properties

| Typical Properties | Value |

|---|---|

| Solids Content | 48.5 - 50.5% |

| pH Value | 7 - 8.3 |

| Viscosity (Brookfield; #2, 30 rpm, 25°C, 30 seconds) | 600 - 1200 cps |

| Density | ~ 1.05 g/cm3 |

| Minimum Film-Forming Temperature (MFFT) | ~ 19°C |

| Acid Value (on solids) (calculated) | ~ 7 mg KOH/g |

| Freeze/Thaw Stable | No |