CoatOSil 1211C

CoatOSil 1211C

CoatOSil® 1211C coatings additive is uniquely engineered and may impart non-foaming and superwetting properties in waterborne coatings for spray applications, high speed roll applications and hard to wet surfaces. It is a 100% active, organomodified silicone that should not interfere with recoatability. It may be an effective replacement for fluorosurfactants in many applications, yet it does not cause the foaming problems often associated with fluorosurfactants. It may also be used in solvent-based and radiation-curable coatings and may enhance the wetting power of the coatings formulations.

CoatOSil 1211C coatings additive may provide the greatest benefit in waterborne formulations to be applied to hard to wet substrate. The non-foaming characteristics may make it well suited for use in coatings applied by spray or high speed roll methods. Possible applications for coatings containing CoatOSil 1211C coatings additive include:

- Coatings for plastic films and plastic components

- Wood coatings

- Glass coatings

- Coatings applied to contaminated (oily) metal surfaces

- Spray or high speed roll applied coatings

To learn more about Momentive Silanes for Coating Applications, check out the Momentive Paint and Coatings Brochure!

Features & Benefits

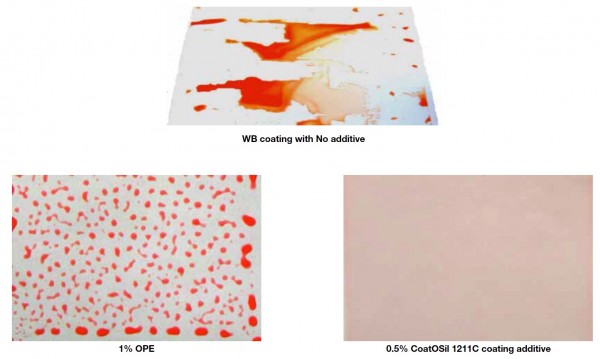

- Helps enable wetting of waterborne systems on hard to wet as well as standard substrates

- May enhance coatings uniformity

- May enable wetting with reduced levels of coalescing agents, hence reduces the levels of volatile organic compounds (VOC) in coatings formulations

- Does not cause foaming in waterborne coatings or inks

- Does not affect recoatability

- May improve dispersion stability of pigments, and color acceptance

Performance Data

10 micro liter aliquot of an aqueous sample was withdrawn using an automatic pipette and discharged onto a clean Polystyrene Petri dish which was conditioned in an enclosed chamber containing humidity in 30% – 70% range. The liquid was allowed to spread for 30 seconds and the edge of surface covered by the liquid was quickly marked using a marker. The area of the spreading surface was then measured.

| Sample Concentration | No Additive | 0.1% CoatOSil 1211C Coating Additive | 0.5% CoatOSil 1211C Coating Additive | 0.5% Benchmark1 |

| Spreading Area (cm2) | 0.15 | 3 | 8 | 0.9 |

1 Benchmark contains an organic surfactant and a defoaming agent.

*Test results, actual results may vary

Properties

| Actives, % | 100 |

| Water Solubility | Dispersible |

| Colour | Light Yellow |

| Specific Gravity @ 25°C | 0.997 |

| Surface Tension, 0.1% (w/w) in water @ 25°C | 22 mN/m |

| Flash Point, °C (°F) | 118 (245) |

| Viscosity, Centipoises @ 25°C | 120 |