Glycolube P Grades

Glycolube P Grades

Glycolube™ P Grades additive is an effective lubricant for many polymer compounds in both extrusion and molding processes. It is recommended for use as a mold release agent in polycarbonate, thermoplastic polyesters, and other engineering thermoplastics.

Polycarbonate polymers are used to produce a variety of materials and are useful when impact resistance and/or transparency are a product requirement (e.g. in bullet-proof glass).

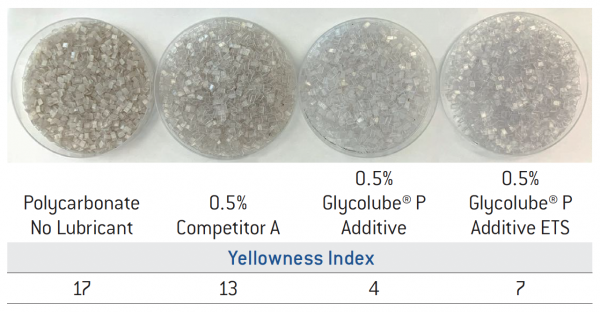

This multifunctional lubricant’s thermal stability allows for use in polycarbonate systems without degrading at processing temperatures. It also exhibits external lubricity while improving haze compared to competitive lubricants. Good external lubrication can come at the cost of increased haze in the final polycarbonate product, but Glycolube P additives maintain strong clarity of the final product

Available Grades:

- Glycolube P

- Glycolube P (ETS)

- Glycolube P VEG KFG

Features & Benefits

- Pentaerythritol Ester: good compatibility with PET & PC

- Flowable beads

- Non-polar lubricant

- Reduces heat dissipation

- Easy to incorporate and compound into PET & PC

- Enhanced clarity in plastic product

- Reduces melt viscosity

Performance Data

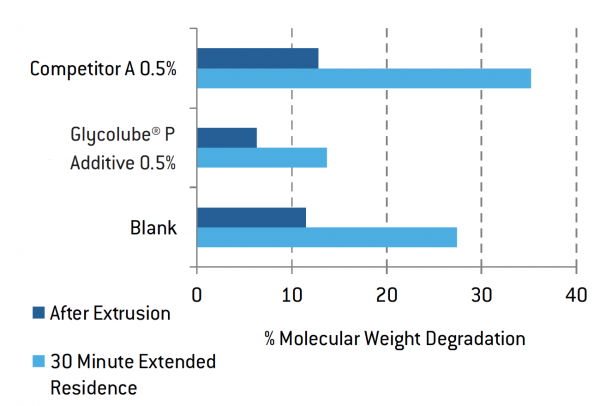

Risk of Thermal Degradation to Product Quality

Thermal degradation of polymer materials while undergoing the high heat and shear of the extrusion process will have a significant impact on the physical quality and appearance of the final product. A large-scale study of rheological behavior was performed to characterize the effect of lubricants on viscosity at various shear rates. By using the Mark-Houwink relationship, it is evident that Glycolube P additive not only protects the polymer from molecular weight degradation during the course of typical extrusion (about 3.5 minutes in this case) but also maintains molecular weight over even longer extruder residence times.

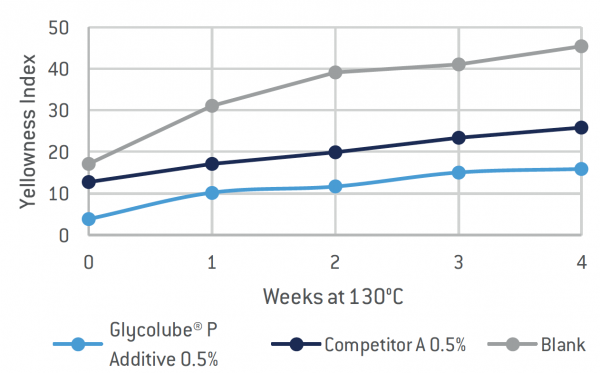

In addition to thermal degradation during processing, thermal degradation after production is of concern. Especially in automotive applications and other similar markets. An aggressive heat-aging protocol was used to test thermal stability, where extruded polycarbonate was held in an oven at 130°C for 4 weeks, with color measurements taken weekly.

Use of Glycolube P additive not only delivers lower yellowness post-extrusion but also maintains low yellowness over time, with a smaller over-all increase compared to both the blank and competitive product.

Properties

| Acid Value | Melting Point | Particle Size ST-10M | Particle Size ST-100M | RSPO Certified | VEG Based | |

|---|---|---|---|---|---|---|

| Glycolube P | 1 max | 60 - 65 | 98% min | 5% max | No | No |

| Glycolube P (ETS) | 2 max | 60 - 65 | 100% min | 10% max | No | No |

| Glycolube P VEG KFG | 2 max | 60 - 65 | 100% min | 10% max | Yes | Yes |