IRGASTAB PUR 70

IRGASTAB PUR 70

IRGASTAB® PUR 70 is an anti-scorch package for polyol and polyurethane (PU) foams that enables customers to meet emissions requirements for the automotive industry

Anti-scorch systems are synergistic combination of additives needed to prevent thermo-oxidative degradation of Polyol and PUR foams. Anti-scorch synergistic packages provide superior scorch protection than single antioxidants. The proper anti-scorch loading must be determined to ensure the required scorch protection, whereas the composition (amine-based, low-amine or amine-free) is key to meet foam end application requirements.

IRGASTAB PUR 70 is a novel anti-scorch additive that provides extremely low emissions and reduces significantly the aldehyde emissions in Polyol and PUR foams. This addresses the increasing challenge to meet emissions requirements of the automotive industry as well as in the furniture and bedding industry. Due to its outstanding gas fading resistance and light-induced discoloration IRGASTAB PUR 70 can be used in applications outside automotive where foam whiteness is key.

Although it was developed primarily for medium density molded foams, where VOC emissions are most problematic, IRGASTAB PUR 70 can be used across a broad density range of flexible foams in automotive and other applications.

IRGASTAB PUR 70 can also be applied in combination with additional antioxidants, co-stabilizers (e. g. phosphites), and/or light stabilizers (e. g. HALS, UVA).

Features & Benefits

- VOC and FOG emissions are greatly reduced

- In automotive applications, the prevention of aldehyde emission improves passenger health and safety

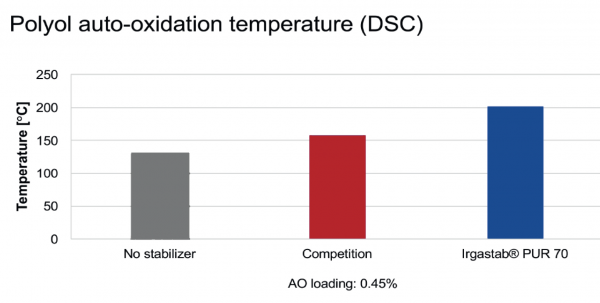

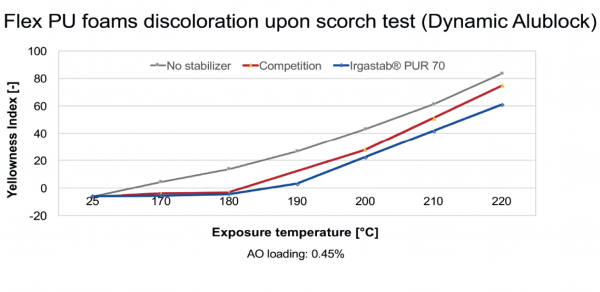

- Prevention of foam scorching/discoloration from thermal stress during processing, leading also to reduced waste

- Exceptional processing stabilization reduces production down time

- Inert to noxious gases, reducing product discoloration

- Liquid formulation improves handling and dosing, saving customer time

- Amine-free stabilizer provides improved health and safety profile

Sustainability Benefits

- Resource efficiency

- Health and safety

- Emission reduction

- Waste reduction

- Cost saving downstream

Performance Data

See the IRGASTAB PUR 70 – Value Card for more performance highlights

Properties

Boiling point…………………… > 200 °C

Viscosity (40 °C)……………… 350 – 500 mm2/s

Relative density (20 °C) …… 0.95 – 1.10

Vapor pressure (20 °C) ……. < 0.1 mbar

Water solubility ………………. partly soluble

Dosage:

- In slabstock polyol applications, the concentration of IRGASTAB PUR 70 ranges between 0.4 % and 0.45 % depending on the degree of stabilization desired.

- In moulding polyol grades, levels of 0.05 % to 0.1% of IRGASTAB PUR 70 are recommended.

- Additional performance data in polyols are available upon request