PORTARYTE®

PORTARYTE®

PORTARYTE® products improve dispersion, provide gloss control and viscosity using white ground baryte. Baryte is available in the market in its ground form and as precipitated material. The main chemical component of both is barium sulphate (BaSO₄).

In order to make the ground material more useful for demanding applications such as paints, plastics, and adhesives, several steps are required. The outcome is a white ground product that resembles precipitated baryte in a lot of properties. Both are relatively soft with Mohs’ hardness of 3 – 3.5. They are chemically inert and insoluble in water, acids, and alkalis. Both have a density of approximately 4.4 g/cm3, making it unusually heavy for a non-metallic mineral. The high density is responsible for its added value in many applications. On other properties, white ground baryte competes or even outperforms precipitated baryte.

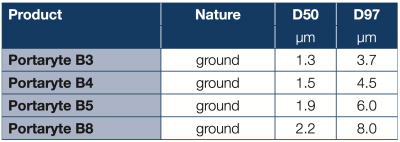

Grades Available

| PORTARYTE® B3 | PORTARYTE® B4 | PORTARYTE® B5 | PORTARYTE® B8 |

Performance Data

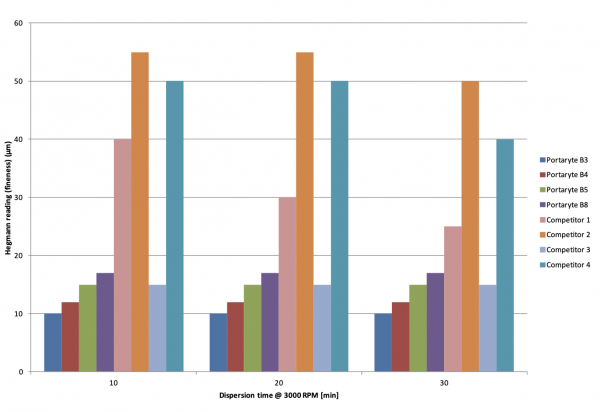

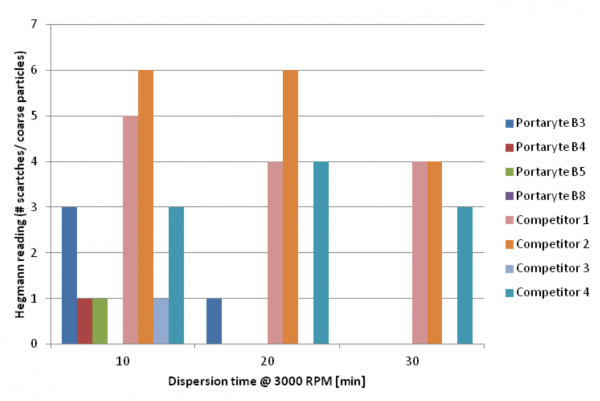

Dispersibility

To determine the dispersibility of the materials, the barytes were added to a commercially available solvent-borne alkyd varnish at a PVC of 30%. The dispersion process was performed using a high speed dissolver at a speed of 3000 RPM. the dispersion was evaluated using a Hegmann gauge, focusing on the number of undispersed particles and the overall fineness.

Figure 1: shows that the ground material as well as Competitor 3 reach their final Hegmann reading within the first 10 minutes. For all the other precipitated grades, this takes at least 30 minutes or more. In general, ground baryte products seem to disperse easier compared to the synthetic baryte products. This is confirmed when looking at the number of aggregates still available.

Figure 2: confirms earlier findings that the ground material is easier to disperse. This can be seen for all PORTARYTE® grades. Again, complete dispersion for the Covia products is obtained within 10 minutes except for the finest grade (PORTARYTE B3), which requires a minimum of 20 minutes.

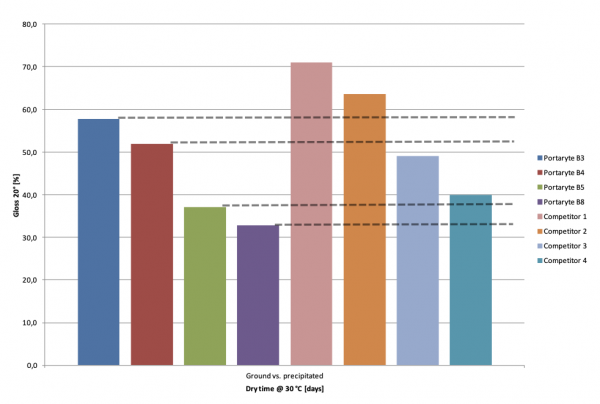

Gloss

To determine the influence on the gloss of a commercially available solvent-borne alkyd varnish, the materials were added up to a PVC of 15%. The dispersion process was performed using a high speed dissolver at a speed of 3000 RPM. The final dispersion was applied on glass plates at a wet film thickness of 90 μm and stored at 30°C. The gloss level was determined after 14 days, at an angle of 20°C.

Figure 3: shows that ground barytes like PORTARYTE® can replace precipitated grades, depending on the required property. When going for high gloss, finer grades such as PORTARYTE® B3 and B4 can be used to replace precipitated products. Going for a matting effect, coarser grades such as PORTARYTE® B5 and B8 can be used.

Properties

PORTARYTE® B3 | PORTARYTE® B4 | PORTARYTE® B5 | PORTARYTE® B8