Starvis 3040 F

Starvis 3040 F

Starvis® 3040 F is a stabilizer in powder form based on water-soluble high molecular weight polymers that prevents bleeding and segregation of mineral particles and aggregates.

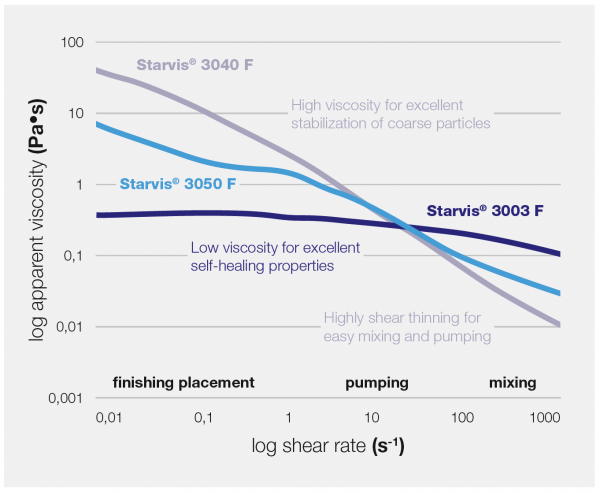

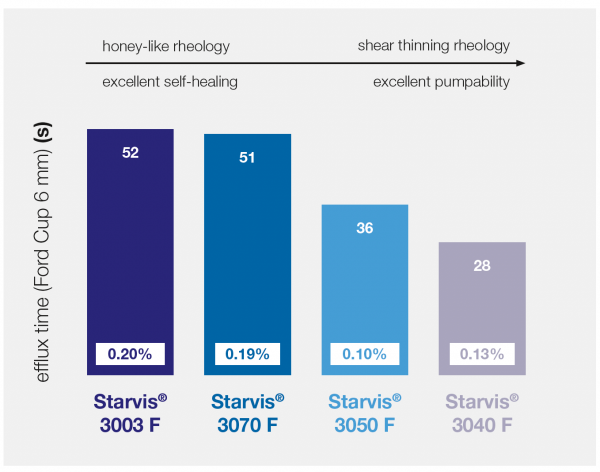

Starvis 3040 F is a high-performance viscosity-enhancing agent is a stabilizer for SLUs and flowing floor screeds with coarse particles and medium to high layer thickness, providing strong shear thinning rheology which reduces pumping pressure.

It is suitable for stabilization of very fluid cement and calcium sulphate-based mixtures. (A high concentration version for higher rate applications, Starvis 3090, is available – ask us for details).

Applications

- Calcium sulphate-based flowing floor screeds

- Cementitious flowing floor screeds

- Cementitious self-leveling underlayments (SLUs)

- Calcium sulphate hemihydrates based self-leveling underlayments (SLUs)

- Cementitious self-leveling decorative overlayments (SLOs)

- Cementitious self-leveling industrial floors

- Non-shrink grouts (machinery grouts)

- Cementitious injection mortars

Features & Benefits

- High viscosity at low shear rates and fast restructuring after shear

- Excellent stabilization of fine and coarse filler particles after placement

- High shear thinning

- Easy mixing and pumping

- Fast Flow speed

- Allows good flow and leveling

For more information on Starvis Stabilizers, check out the Technical Leaflet!

Performance Data

Properties

| Technical Data | Value |

| Physical Shape | Powder |

| Appearance | Characteristic, white to yellowish |

| Drying Loss, % | Max. 4.0 |

| Bulk Density, kg/m3 | 750 to 1050 |

| pH Value (20°C, 2% solution) | 8.0 to 11.0 |

| Dosage Recommendation (%), in relation to weight of dry mortar | 0.01 to 0.50 |