Societies, international organizations, governments and the international business community are increasingly aware of the need to take action to balance economic, environmental and social interests. In 2010 alone, the world’s population consumed 1.5 times the renewable capacity of our planet. If the trend continues, we will need resources equivalent to three Earths to meet demands by 20501.

When a paint company embarks on the journey to improve the sustainability of their processes and products, it can be hard to know where to begin. With an end-goal in sight, planning the steps and prioritizing them can be a daunting task. The good news is that working towards sustainability can go hand-in-hand with innovation and cost-savings back to the company. A more efficient manufacturing process for example earns checks mark for reducing energy consumption and utilization of raw materials.

The journey can start with a few small steps that offer big impact. That’s where formulation additives come in!

Additives are Enablers for Innovation and Sustainability

✔ Enhance the environmental compatibility

✔ Enhance resource efficiency of your systems

✔ Improving the impact on health and wellbeing

Dispex® Ultra FA 4480 and 4483

Universal wetting / dispersing agents for pigment concentrates

Formulation additives support more sustainable paints and coatings by shortening dispersion and production time. Pigment dispersion is the most energy-consuming phase in paint production. A highly efficient dispersing agent accelerates the process during grinding and helps achieve maximum color strength and stability with lowest-possible viscosity. The result: greater pigment efficiency and reduced emissions!

Dispex® Ultra FA 4480 / FA 4483 offer solutions for water-based pigment concentrates. Together, they are used to formulate APEO-free and glycol-free universal colorants.

Performance Highlights

- Excellent pigment stabilization, viscosity reduction and wetting and dispersing properties

- lmproved stability and colour intensity of pigment concentrates

- Excellent compatibility with aqueous and solvent-based systems

- Anti-settling effect

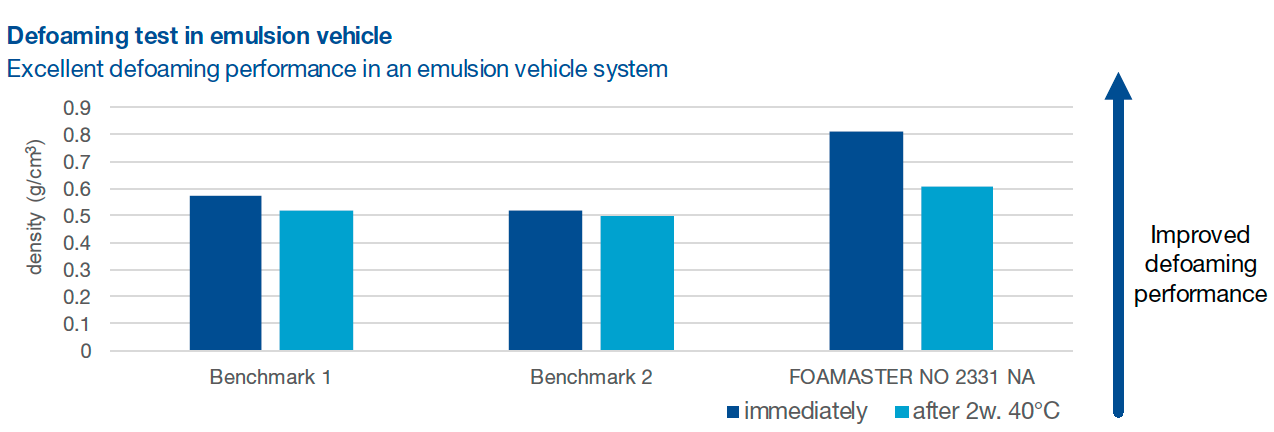

Foamaster® NO 2331 NA

Environmentally sound, natural oil-based alternative to mineral oil defoamers

By reducing foaming, additives can boost production capacity and allow fast and accurate filling of cans. Foaming, whether it occurs during dispersion, pumping or stirring processes, slows paint production. Special grind defoamers accelerate production and boost overall capacity by preventing air from entering during the process. Easy-to-blend defoamers added in the let-down phase support fast and accurate filling into final packaging (cans and containers), while also helping prevent foam from forming during transport to the point of sale.

Foamaster® NO 2331 NA is a natural-oil based, VOC-free and low SVOC defoamer, which provides excellent performance and minimizes haze and fogging often seen with mineral oil defoamers. lt is suitable for all types of aqueous premium paints (high PVC, premium flat & eggshell

Performance Highlights

- Quick foam suppression

- Highly compatible

- Excellent long-term stability

- Low influence on gloss

- Broad applicability

- Low fogging

- Excellent product stability

Loxanol® CA 5310

Emission free coalescing agent to reach <50 g/l VOC

Loxanol CA 5310 contains over 80% renewable content and can replace traditional VOC contributing coalescent.

Traditional coalescent vaporize contributing towards VOC. However, Loxanol CA 5310 remains in the paint film, providing a long lasting coalescing effect and increases the total solids content of the system.

Performance Highlights

- Renewable based low VOC coalescing aid: >80% renewable content

- Synergistic benefit with rheology modifiers: reduce amount of rheology modifiers added

- Stability of small particle size polymers enhanced in conjunction with TiO2 usage:

- Tint strength and contrast ratio (opacity) optimized

- Utilize less opacifying aids

- High efficiency: positive impact on block resistance and film hardness resulting in better stain resistance (interior) and better dirt pick-up resistance (exterior)

- Less impact on hiding power: improved tint strength and contrast ratio

- Does not contribute to the VOC content of the paint

- Low odor

- Good low-temperature cure

- Non-yellowing

- Non-hazardous

What is Sustainable Solution Steering from BASF?

No general standard is currently in place for assessing a product’s contribution to sustainability in the paint and coatings industry. In response, BASF has developed the Sustainable Solution Steering methodology. It establishes clear evaluation criteria and process steps including roles and responsibilities in an internal set of guidelines.

Have Questions? We’re here to help!